Cov khoom

Alumina hmoov rau polishing

Alumina hmoov yog qhov zoo tagnrho rau cov khoom siv txhuas thiab lwm yam uas yuav tsum tau ua kom tawv thiab ua haujlwm rau kev puas tsuaj lossis lwm hom tshuaj hnav. Alumina hmoov kuj zoo tagnrho rau cov khoom uas yuav tsum tau corrosion thiab hnav tsis kam, thiab rau cov khoom uas yuav tsum tau thermal conductivity, xws li hluav taws xob thiab thermally insulating daim ntaub ntawv.

Product Performance:

Cov khoom yog cov hmoov dawb los yog cov xuab zeb zoo thiab muaj kev ua haujlwm zoo sintering. Insoluble hauv dej, insoluble hauv acid, alkali daws. Lub particle loj ntawm protocrystal yog tswj tau.

Alumina hmoov Specifications

| Cov nplej | 0.3μm, 0.5μm, 0.7μm, 1.0μm, 1.5μm, 2.0μm, 3.0μm, 4.0μm, 5.0μm | ||||||

| Specifications | AI2O 3 | Na2O | D10 (hli) | D50 (hli) | D90 (hli) | Tus thawj crystal grain | thaj chaw tshwj xeeb (m2 / g) |

| 0,7 ua | ≥99.6 | ≤ 0.02 | > 0.3 | 0.7-1 | 6 | 0.3 | 2-6 |

| 1.5 ua | ≥99.6 | ≤ 0.02 | > 0.5 | 1-1.8 | 10 | 0.3 | 4-7 |

| 2.0 ua | ≥99.6 | ≤ 0.02 | > 0.8 | 2.0-3.0 Nws | <17 | 0.5 | 20 |

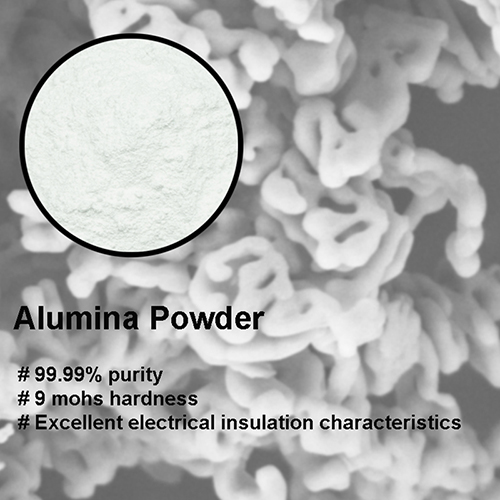

Alumina hmoov yam ntxwv:

1. Tshuaj tiv thaiv

2. High-purity alumina, cov ntsiab lus alumina ntau dua 99%

3. Kev kub siab ua haujlwm, kev ua haujlwm kub yog 1600 ℃, mus txog 1800 ℃

4. thermal shock tsis kam, ruaj khov thiab nyuaj rau tawg

5. Moulding los ntawm casting, nws muaj qhov ntom ntom

Alumina hmoov muaj qhov zoo ntawm purity siab thiab ceev ceev, feem ntau yog siv hauv ceramics, iav, plastics, textiles, tsev cov ntaub ntawv, abrasives, ntawv thiab tshuaj, thiab ntau lwm yam teb.

Alumina hmoov Advantage:

1.Los ntawm airflow zeb thiab tsib txheej kev faib tawm, cov nplej loj faib yog nqaim, kev sib tsoo ua haujlwm siab, cov nyhuv polishing zoo, kev sib tsoo efficiency ntau dua li cov mos abrasives xws li silica.

2.zoo particle tsos, qhov saum npoo ntawm cov khoom yuav polished muaj ib tug high degree ntawm smoothness, nyob rau hauv lub kawg zoo polishing txheej txheem, cov nyhuv ntawm kev sib tsoo thiab polishing yog zoo dua li dawb corundum hmoov.

1.Xov tooj tshuaj ntsuam polish, nrog rau qhov kawg polishing rau sapphire xov tooj ntawm tes npo, xov tooj ntawm tes iav npo. Kuj tseem siv tau: pob zeb diamond, zircon, qib siab iav, ntuj pob zeb, jade, agate thiab lwm yam vibratory xov (tshuab polishing, yob polishing), phau ntawv polishing (sib tsoo polishing) thiab lwm yam.

2.Metal polishing, suav nrog lub xov tooj ntawm tes, lub log tsheb, cov khoom siv qib siab kawg polishing.

3.Widely siv nyob rau hauv kev sib tsoo thiab polishing ntawm semiconductors, muaju, txhuas, hlau, stainless hlau, pob zeb, iav, thiab lwm yam.

4.Tshwj xeeb yog tsim rau cov iav nyhuv sib tsoo thiab polishing ntawm stainless hlau, tooj liab, lwm yam ntaub ntawv hlau, thiab iav kev lag luam.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.