Cov khoom

Hlau abrasive Steel Grit Blast Media

STEEL GRIT

Cov xov xwm txhoj puab heev no yog siv hauv blasting thiab stripping steel thiab foundry hlau. Steel Grit zoo tsim ib qho etching ntawm cov hlau tawv kom zoo dua adhesion ntawm coatings nrog rau cov xim, epoxy, enamel thiab roj hmab. Kev siv suav nrog kev tsheb ciav hlau kho tsheb, tshem tawm flashing, blasting txuas hniav, hlau qhov chaw thiab forging kev lag luam daim ntawv thov.

| Cov khoom | Hlau Grit | |

| Tshuaj muaj pes tsawg leeg | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤ 0.05% | |

| P | ≤ 0.05% | |

| Hardness | Hlau txhaj | GP 41-50HRC; GL 50-55HRC; GH 63-68HRC |

| Qhov ntom | Hlau txhaj | 7.6g 3 |

| Micro qauv | Martensite qauv | |

| Qhov tshwm sim | Spherical Hollow hais <5% Crack particle <3% | |

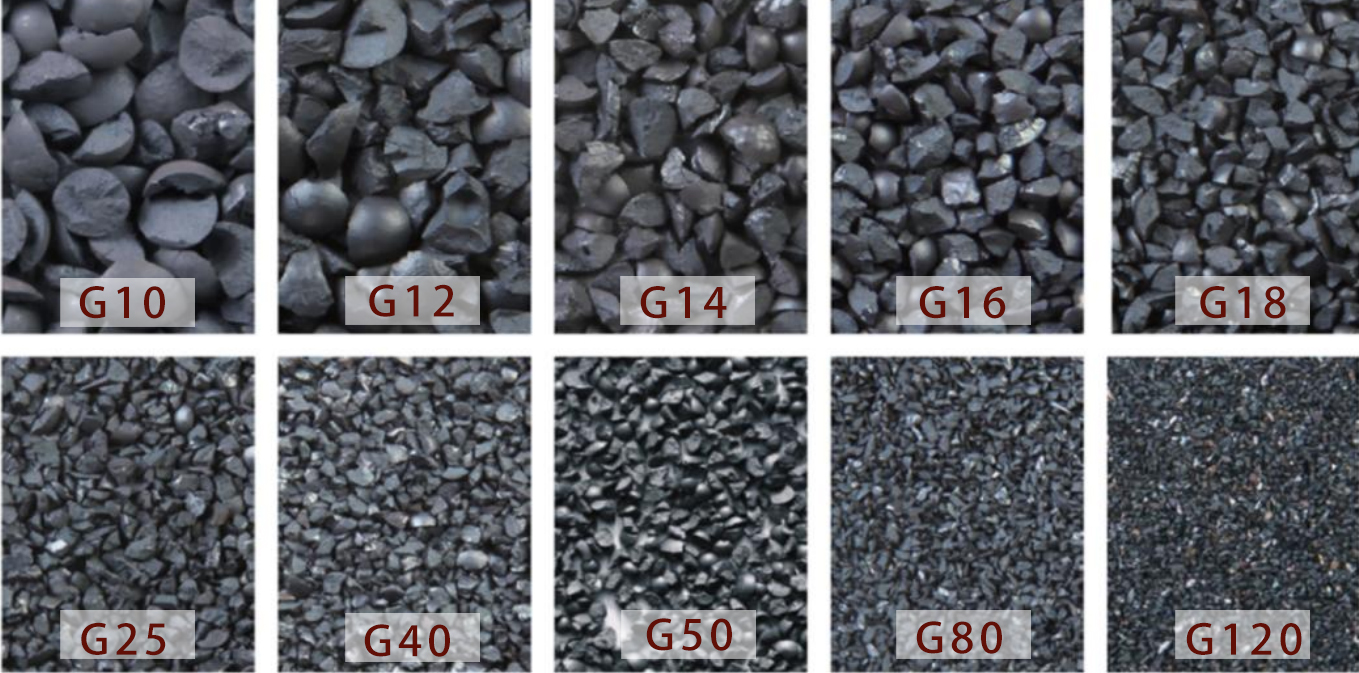

| Hom | G120, G80, G50, G40, G25, G18, G16, G14, G12, G10 | |

| Txoj kab uas hla | 0.2 hli, 0.3 hli, 0.5 hli, 0.7 hli, 1.0 hli, 1.2 hli, 1.4 hli, 1.6 hli, 2.0 hli, 2.5 hli | |

Daim ntawv thov Steel Grit

1.Surface Preparation: Steel grits yog dav siv rau saum npoo ntawm kev npaj ua ntej siv txheej, xim, los yog adhesives. Lawv tshem tawm cov xeb, nplai, cov coatings qub, thiab cov kab mob ntawm cov hlau, kom ntseeg tau tias muaj kev sib raug zoo ntawm cov ntaub ntawv tom ntej.

2.Rust thiab Corrosion tshem tawm: steel grits yog siv los tshem tawm hnyav xeb, corrosion, thiab zeb nplai los ntawm cov hlau nto, tshwj xeeb tshaj yog nyob rau hauv kev lag luam xws li shipbuilding, marine tu, thiab structural steel fabrication.

3.Kev npaj rau Vuam: Ua ntej vuam lossis lwm yam kev sib koom ua ke, steel grits tuaj yeem siv los ntxuav thiab npaj qhov chaw, kom ntseeg tau tias muaj zog thiab huv cov pob qij txha.

4.Concrete thiab Stone Surface Preparation: Steel grits tuaj yeem siv los ntxuav thiab npaj cov pob zeb thiab pob zeb, xws li rau cov haujlwm kho dua tshiab, qhov twg yuav tsum tau tshem tawm cov txheej qub qub, stains, lossis cov kab mob.

5.Shot Peening: Thaum cov hlau txhaj tshuaj feem ntau yog siv rau kev txhaj tshuaj peening, steel grits kuj tseem siv tau rau cov txheej txheem no. Kev txhaj tshuaj peening muaj kev sib tsoo ntawm qhov chaw nrog cov khoom abrasive kom ua rau muaj kev ntxhov siab, uas ua rau cov khoom siv zog thiab qaug zog.

6.Deburring thiab Deflashing: steel grits yog siv los tshem tawm burrs, ntse npoo, thiab cov khoom siv ntau dhau los ntawm cov khoom hlau, tshwj xeeb tshaj yog nyob rau hauv kev tsim cov txheej txheem uas yuav tsum tau precision thiab smoothness.

7.Foundry Applications: Steel grits yog siv nyob rau hauv foundries tu thiab npaj casting nto, pwm thiab core tshem tawm, thiab dav hlau nto kho. 8.Surface Profiling: Steel grits yog ua hauj lwm los tsim tej yam nto profiles, tshwj xeeb tshaj yog nyob rau hauv industries xws li kev tsim kho thiab shipbuilding. Cov profiles no txhim kho cov txheej txheej adhesion thiab muab kev tuav zoo dua rau cov ntaub nplaum nplaum.

9.Stone Cutting and Etching: Hauv kev tsim kho thiab kev lag luam monument, steel grits yog siv los txiav thiab etching pob zeb thiab lwm yam ntaub ntawv nyuaj, tsim intricate designs thiab qauv.

10.Oil thiab Gas Kev Lag Luam: Hlau grits yog siv rau kev npaj nto hauv kev lag luam roj thiab roj, xws li ntxuav cov kav dej, tso tsheb hlau luam, thiab lwm yam khoom siv.

11.Automotive Industry: Steel grits yuav siv tau rau stripping xim thiab coatings los ntawm automotive qhov chaw, npaj nto rau refinishing los yog kho dua tshiab.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov kev xaiv ntawm qhov tsim nyog steel grit loj, hardness, thiab lwm yam specifications yog nyob ntawm qhov tshwj xeeb daim ntawv thov thiab qhov xav tau nto tiav. Cov khoom abrasive ntawm steel grits ua rau lawv cov cuab yeej tseem ceeb rau kev ua haujlwm uas yuav tsum tau tshem tawm cov khoom zoo thiab kev hloov kho saum npoo.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.