Additive Manufacturing thiab Subtractive Manufacturing: Kev Sib Tham ntawm Kev Siv Pwm Tom Qab Precision Machining

Niaj hnub nimno kev lag luam kev lag luam tau muab cov kev xav tau siab dua rau qhov raug, ua haujlwm tau zoo thiab tsim kev ywj pheej. Ntxiv nrog rau kev tsim cov thev naus laus zis niaj hnub (xws li milling, sib tsoo, thiab lwm yam),Additive manufacturing (3D luam ntawv)thev naus laus zis kuj tau tshwm sim sai heev thiab dhau los ua ib qho tseem ceeb ntawm kev tsim kho tshiab. Ob leeg muaj lawv tus kheej zoo thiab yog dav siv nyob rau hauv lub teb ntawm tsheb, aerospace, kho mob pab kiag li lawm thiab machinery manufacturing. Hauv ob txoj kev tsim khoom no, lub luag haujlwm ntawm pwm yog qhov tseem ceeb tshwj xeeb thiab cuam tshuam ncaj qha rau kev ua haujlwm zoo thiab kev ua haujlwm ntau lawm.

Taw qhia rau Additive Manufacturing Technology thiab Mould Application

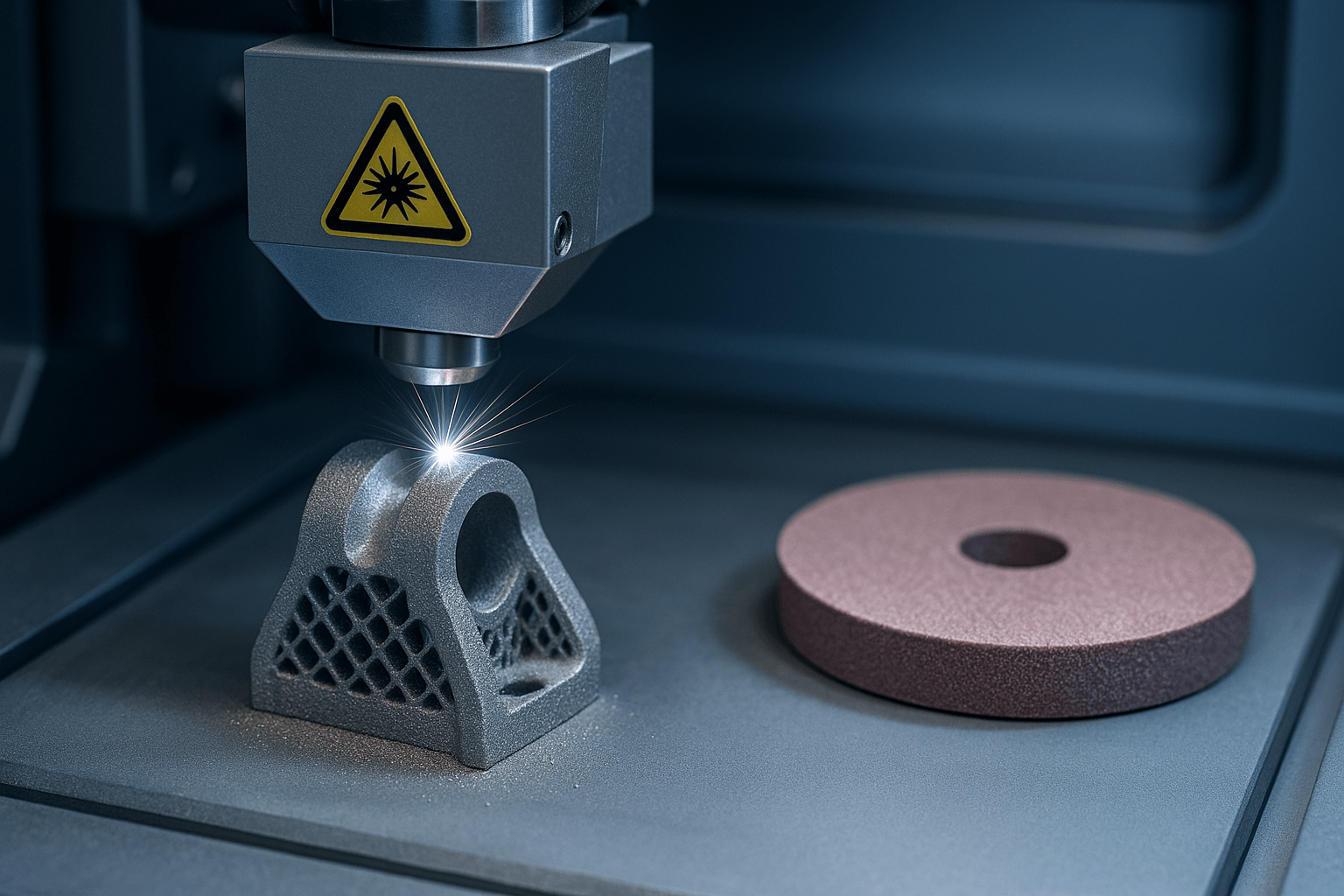

Additive manufacturing, tseem hu ua 3D luam ntawv, yog txheej txheem ntawm lub tsev los ntawm stacking cov ntaub ntawv txheej los ntawm txheej. Cov txheej txheem tsim khoom siv ntau ntxiv suav nrog kev xaiv laser sintering (SLS), xaiv laser melting (SLM), fused deposition modeling (FDM) thiab stereolithography (SLA). Hom tshuab no paub txog nws txoj kev ywj pheej tsim qauv siab heev. Nws tuaj yeem tsim cov khoom siv nrog cov duab thiab cov kab noj hniav sab hauv lossis cov kab sib chaws, nrog rau kev siv cov khoom siv siab thiab txo cov khoom pov tseg. Additive manufacturing yog tshwj xeeb tshaj yog haum rau prototyping sai, me me batch ntau lawm thiab tus kheej customization, thiab yog dav siv nyob rau hauv aerospace, tsheb, khoom kho mob thiab pwm manufacturing. Nws cov txiaj ntsig tseem suav nrog kev ua kom luv luv ntawm txoj kev loj hlob, txhawb kev tsim kho tshiab thiab kev ua tiav ntawm ntau txoj kev daws teeb meem.

Txawm hais tias kev tsim khoom ntxiv tuaj yeem tsim cov qauv tsim ncaj qha, qhov saum npoo ntawm cov ntawv luam tawm feem ntau yog ntxhib, nrog cov kab txheej thiab me me tsis xws luag, thiab tom qab machining yuav tsum tau ua kom tau raws li qhov loj thiab qhov chaw zoo. Lub sijhawm no, kev ua haujlwm zoo abrasives yog cov cuab yeej tseem ceeb. Abrasives xws lisib tsoo log, sanding siv, nrov plig plawg log thiab polishing log yog dav siv rau deburring, nto flattening thiab xov ntawm additive manufacturing qhov chaw kom paub meej tias cov khoom mus txog industrial-qib precision thiab zoo nkauj. Tshwj xeeb tshaj yog nyob rau hauv cov teb ntawm aerospace thiab kev kho mob, cov kev xav tau siab rau saum npoo zoo thiab kev ua haujlwm tau tsav cov abrasives mus txuas ntxiv txhim kho cov khoom ua haujlwm siab thiab hnav-tiv taus kom tau raws li cov kev xav tau tshwj xeeb ntawm kev tsim khoom ntxiv tom qab ua tiav.

Kev taw qhia txog kev tsim khoom siv thev naus laus zis thiab kev siv abrasive

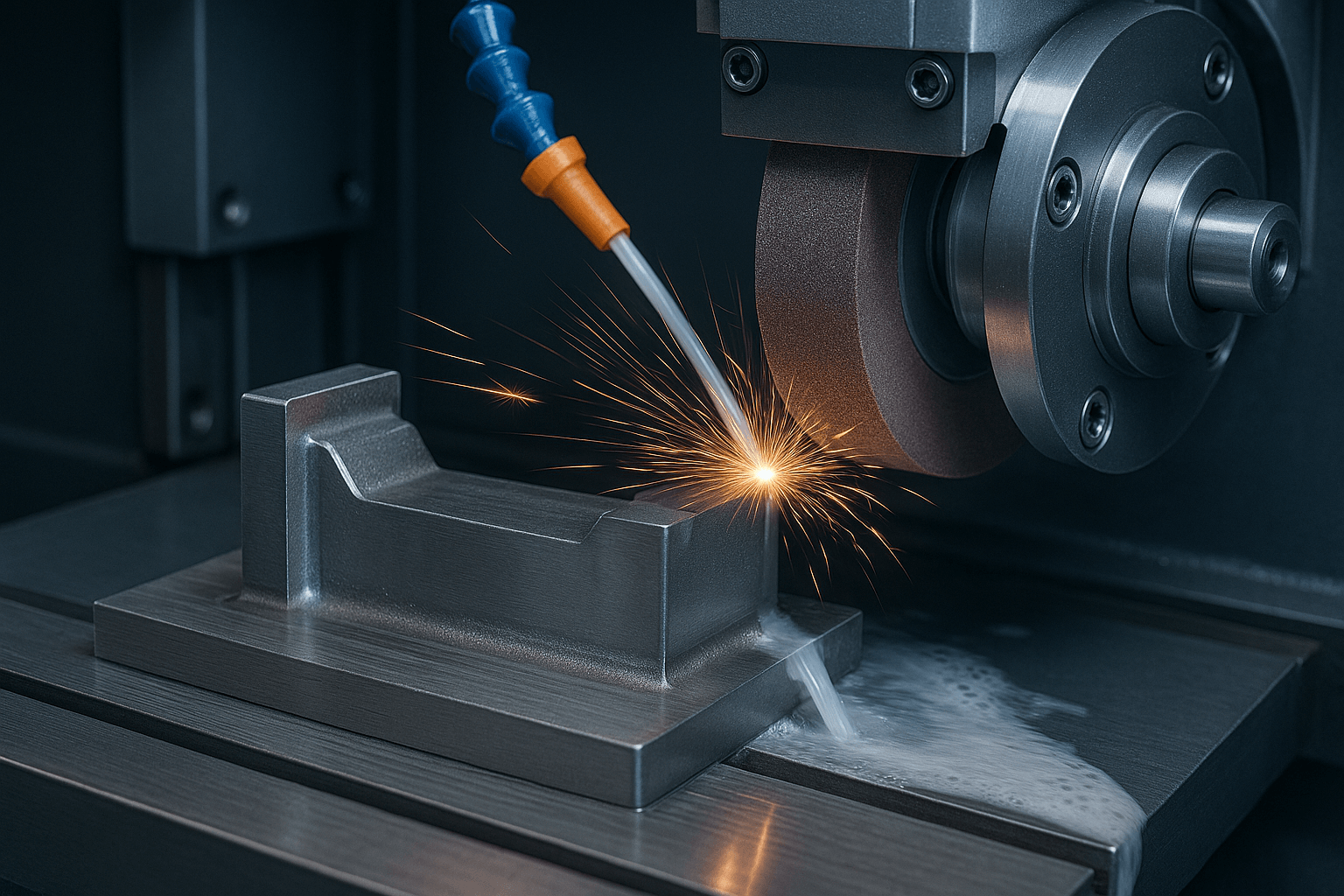

Subtractive manufacturingyog tshem tawm cov khoom siv ntau dhau los ntawm kev txiav, milling, sib tsoo thiab lwm txoj hauv kev los ua cov khoom ua haujlwm rau hauv cov duab ua ntej. Cov tshuab no yog cov paub tab thiab tsim nyog rau kev tsim khoom loj, tshwj xeeb tshaj yog zoo ntawm kev ua kom muaj qhov siab-precision qhov ntev thiab zoo heev saum npoo. Cov txheej txheem muaj xws li CNC milling, tig, sib tsoo, xaim txiav, hluav taws xob tawm machining (EDM), laser txiav thiab dej dav hlau txiav. Subtractive manufacturing plays lub luag haujlwm tseem ceeb hauv kev tsim tsheb, aerospace, machinery manufacturing thiab khoom siv kho mob. Nws tuaj yeem ua cov txheej txheem steel, cam khwb cia hlau, aluminium alloys thiab cov ntaub ntawv sib xyaw kom tau raws li cov kev cai nruj ntawm kev lag luam rau kev ua haujlwm ntev thiab kev ua haujlwm.

Abrasives ua si lub luag haujlwm tseem ceeb hauv kev tsim khoom, tshwj xeeb tshaj yog nyob rau hauv cov txheej txheem sib tsoo. Ntau hom kev sib tsoo log (xws li ceramic sib tsoo log, resin sib tsoo lub log) thiab cov cuab yeej polishing tau dav siv rau kev siv tshuab ntxhib, xov thiab polishing nto raws li cov txheej txheem yuav tsum ua kom ntseeg tau tias qhov chaw ua tiav siab precision thiab iav-theem nto zoo. Abrasive kev ua tau zoo ncaj qha cuam tshuam rau kev ua tau zoo thiab cov khoom lag luam zoo, ua rau muaj kev hloov pauv tas li ntawm cov ntaub ntawv abrasive thiab cov qauv kom tau raws li cov kev xav tau ntawm cov khoom siv hardness siab thiab cov geometry nyuaj.

Raws li tus choj tseem ceeb ntawm ob, abrasives txhawb kev sib txuas seamless los ntawm kev tsim khoom ntxiv mus rau kev tsim tawm. Nrog rau kev siv cov ntaub ntawv sib xyaw thiab cov ntaub ntawv siab hardness, kev txhim kho cov cuab yeej abrasive tau dhau los ua qhov txuas tseem ceeb hauv kev ua kom muaj kev tsim khoom zoo. Hauv kev teb rau cov teeb meem roughness ntawm qhov chaw tshwj xeeb rau kev tsim khoom ntxiv thiab cov kev xav tau siab tshaj plaws ntawm cov khoom tsim tawm, kev tshawb fawb thiab kev tsim cov pwm txuas ntxiv txhim kho kom muaj zog dua, cov qauv zoo dua thiab lub neej ntev dua, txhawb kev txawj ntse thiab kev ua haujlwm ntawm tag nrho cov saw hlau.