Kev siv cov xim av corundum micro hmoov nyob rau hauv daim teb ntawm abrasives

Nrog rau txoj kev loj hlob sai ntawm niaj hnub kev lag luam technology, abrasives, raws li ib tug indispensable ib feem ntawm kev lag luam ntau lawm, muaj ntau yam kev siv. Raws li ib feem tseem ceeb ntawm abrasives, xim av corundum micro hmoov, nrog nws cov cim lub cev thiab tshuaj lom neeg, ua lub luag haujlwm tseem ceeb hauv kev sib tsoo, polishing, lapping thiab lwm yam txheej txheem. Daim ntawv no yuav qhia meej txog daim ntawv thov xim av corundum micro hmoov nyob rau hauv daim teb ntawm abrasives, nrog rau nws qhov tshwj xeeb zoo thiab kev loj hlob yav tom ntej.

I. Cov yam ntxwv ntawm cov xim av corundum micro hmoov

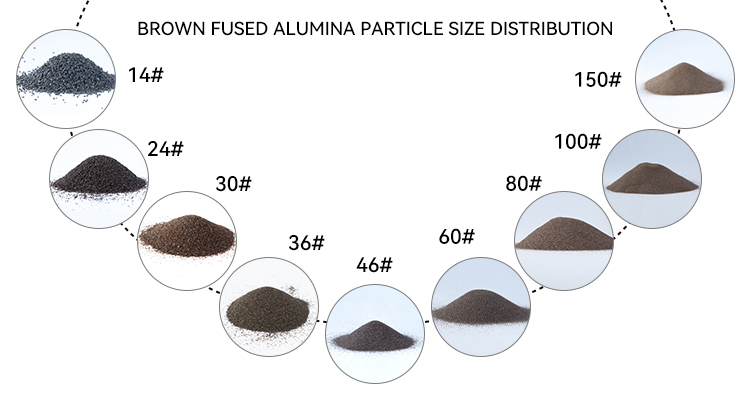

Brown corundum micro hmoovyog ib hom micro hmoov khoom ua los ntawm cov xim av corundum ua raw khoom, tom qab crushing, sib tsoo, grading thiab lwm yam txheej txheem.Brown corundumyog ib hom oxide ntxhia uas muaj siab hardness, siab toughness thiab siab hnav tsis kam, yog li cov micro hmoov ua los ntawm cov xim av corundum kuj muaj cov yam ntxwv no. Brown corundum micropowders muaj nyob rau hauv ntau qhov ntau thiab tsawg, los ntawm ob peb microns mus rau ntau pua microns, thiab tuaj yeem kho raws li cov txheej txheem sib txawv. Tsis tas li ntawd, xim av corundum micro hmoov kuj muaj qhov zoo ntawm cov tshuaj zoo stability, corrosion kuj, zoo thermal conductivity thiab lwm yam.

Kev siv cov xim av corundum micro hmoov nyob rau hauv daim teb ntawm abrasives

Hauv kev ua cov hlau, tsis yog hlau thiab lwm yam khoom siv, feem ntau yuav tsum tau siv cov txheej txheem sib tsoo kom ua tiav qhov yuav tsum tau ua kom raug thiab ua tiav. Brown corundum micropowder yog ib qho kev xaiv zoo tshaj plaws rau cov txheej txheem sib tsoo vim nws qhov siab hardness thiab zoo hnav tsis kam. Ntxiv tus nqi ntawm cov xim av corundum hmoov rau cov cuab yeej sib tsoo tuaj yeem txhim kho kev sib tsoo zoo thiab zoo ntawm cov cuab yeej sib tsoo, thiab txuas ntxiv lub neej kev pab cuam ntawm cov cuab yeej sib tsoo.

Polishing yog ib qho txheej txheem tseem ceeb los txhim kho qhov ua tiav ntawm qhov chaw ua haujlwm. Brown corundum hmoov muaj ntau yam kev siv hauv cov txheej txheem polishing. Vim tias nws cov duab zoo li niaj zaus, thiab siab tawv, hnav tsis kam yog qhov zoo, yog li nws tuaj yeem tshem tawm cov pob me me ntawm qhov chaw ua haujlwm, kom lub ntsej muag ntawm lub workpiece smoother. Tsis tas li ntawd, xim av corundum hmoov kuj tuaj yeem siv nrog lwm cov ntaub ntawv polishing los txhim kho cov nyhuv polishing.

Kev sib tsoo yog hais txog qhov kev txiav txim ntawm abrasive, kom lub ntsej muag ntawm lub workpiece kom tiav ib qho kev ua tiav thiab qhov tseeb. Brown corundum micro hmoov kuj tseem muaj daim ntawv thov tseem ceeb hauv kev sib tsoo. Vim nws qhov ntau ntawm particle loj, nws tuaj yeem xaiv raws li kev sib tsoo sib txawv. Nyob rau tib lub sijhawm, tshuaj lom neeg ruaj khov ntawm cov xim av corundum hmoov yog qhov zoo, yuav tsis ua rau corrosion ntawm lub workpiece, los xyuas kom meej qhov kev sib tsoo zoo thiab qhov chaw zoo ntawm lub workpiece.

Qhov zoo ntawm cov xim av corundum hmoov hauv abrasives teb

1. siab hardness thiab hnav tsis kam: xim av corundum hmoov muaj siab hardness thiab hnav tsis kam, uas tuaj yeem txhim kho kev sib tsoo efficiency thiab kev pab cuam lub neej ntawm cov cuab yeej sib tsoo.

2. zoo tshuaj stability:xim av corundum hmoovmuaj kev ruaj ntseg tshuaj zoo, yuav tsis ua rau corrosion mus rau lub workpiece, los xyuas kom meej kev sib tsoo zoo thiab nto zoo ntawm lub workpiece.

3. Ntau yam ntawm cov nplej loj:xim av corundum micro hmoovmuaj ntau yam ntawm cov nplej loj, uas tuaj yeem ua raws li cov txheej txheem sib txawv kom tau raws li qhov xav tau ntawm ntau yam abrasives.

4. Kev siv ntau yam: xim av corundum micro hmoov tsis yog tsuas yog siv rau hauv kev sib tsoo, polishing, lapping thiab lwm yam txheej txheem, tab sis kuj nyob rau hauv lwm yam teb, xws li coatings, roj hmab, plastics thiab lwm yam lag luam.