Taw qhia thiab siv cov pob zeb diamond abrasives

Pob zeb diamond yog ib yam khoom uas muaj hardness siab tshaj plaws nyob rau hauv cov xwm. Nws muaj cov hardness siab heev, thermal conductivity thiab hnav tsis kam, yog li nws yog dav siv hauv kev lag luam abrasive. Nrog rau txoj kev loj hlob ntawm industrial technology,pob zeb diamond abrasivestau tsim los ntawm cov pob zeb diamond ib txwm siv rau ntau yam khoom siv dag zog thiab cov khoom siv sib xyaw ua haujlwm, dhau los ua ib feem tseem ceeb ntawm cov ntaub ntawv superhard, thiab tau siv dav hauv ntau qhov kev lag luam siab xws li kev ua tshuab, hluav taws xob, optics, thiab lub zog tshiab.

Ⅰ. Basic qhia txog pob zeb diamond abrasives

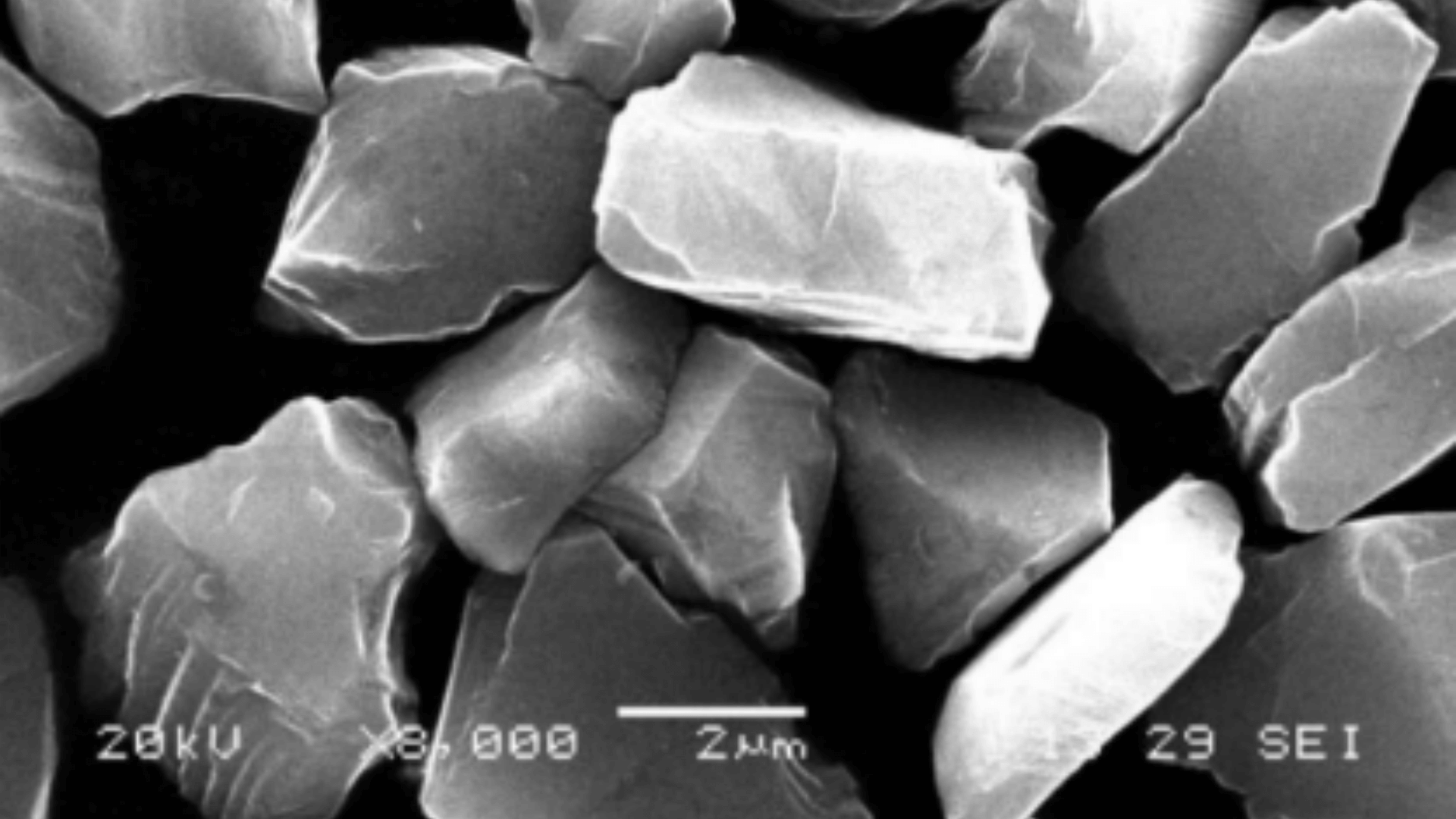

Pob zeb diamond abrasives yoghmoov los yog granular cov ntaub ntawv ua los ntawm crushing, tshuaj ntsuam, thiab purification ntawm ntuj pob zeb diamond los yog dag pob zeb diamond. Nws Mohs hardness mus txog qib 10, uas yog lub siab tshaj plaws paub abrasive. Piv nrog cov tsoos abrasives xws li txhuas oxide thiab silicon carbide, pob zeb diamond abrasives muaj peev xwm txiav ntau dua thiab hnav tsis kam, thiab tuaj yeem zom thiab txhuam cov ntaub ntawv hardness siab nrog kev ua haujlwm siab thiab kev puas tsuaj tsawg.

Pob zeb diamond abrasives feem ntau suav nrog cov ntaub ntawv hauv qab no:

Pob zeb diamond micropowder: Qhov luaj li cas ntawm kaum ntawm microns mus rau nanometers, haum rau ntau yam kev ua haujlwm siab polishing.

Pob zeb diamond sib tsoo log / sib tsoo lub taub hau: siv rau kev sib tsoo thiab shaping ntawm cov ntaub ntawv nyuaj.

Pob zeb diamond pom hniav / laum me ntsis: siv rau kev txiav thiab drilling cov ntaub ntawv xws li pob zeb, ceramics, iav, thiab lwm yam.

Pob zeb diamond sib tsoo kua / polishing muab tshuaj txhuam: dav siv nyob rau hauv ultra-precision ua nyob rau hauv electronics, optics, pwm thiab lwm yam lag luam.

Cov khoom siv pob zeb diamond sib xyaw (PCD / PCBN): sib txuas cov pob zeb diamond nrog hlau lossis ceramic matrix los tsim cov khoom siv sib xyaw nrog cov tawv thiab hnav tsis kam.

Ⅱ. Daim ntawv thov teb ntawm pob zeb diamond abrasives

1. Mechanical processing

Pob zeb diamond abrasives yog dav siv nyob rau hauv shaping thiab sib tsoo ntawm high-hardness cov ntaub ntawv, xws li cemented carbide, ceramics, silicon carbide, iav, ferrite, thiab lwm yam. Siv pob zeb diamond sib tsoo log rau kev ua tsis tau tsuas yog ho txhim kho kev ua hauj lwm efficiency thiab nto zoo, tab sis kuj ntev lub neej thiab txo cov cuab yeej hloov zaus. Nws yog tshwj xeeb tshaj yog haum rau loj-tsim, automated high-precision manufacturing txheej txheem.

2. Electronics thiab semiconductor industries

Thaum lub sij hawm ua cov ntaub ntawv xws li silicon wafers, sapphire substrates, silicon carbide chips, optoelectronic iav, thiab lwm yam., pob zeb diamond hlau saws, sib tsoo kua thiab polishing pastes yog qhov tseem ceeb consumables. Pob zeb diamond abrasives tuaj yeem ua tiav submicron lossis txawm tias nanometer-theem flatness thiab roughness. Lawv tau siv dav hauv cov kev sib txuas tseem ceeb xws li chip dicing, wafer sib tsoo, thiab photomask polishing. Lawv yog ib qho tseem ceeb hauv kev ua kom muaj kev ua tau zoo thiab cov txiaj ntsig siab ntawm cov khoom siv hluav taws xob.

3. Optical ua

Pob zeb diamond hmoov yog dav siv nyob rau hauv polishing ntawm optical iav, laser qhov rais, sapphire lo ntsiab muag thiab lwm yam khoom. Nws zoo heev txiav quab yuam thiab tshuaj stability tuaj yeem txhim kho qhov zoo ntawm daim iav ua thiab ua tiav qhov roughness Ra ntawm tsawg dua 10nm. Nws yog ib qho khoom siv tseem ceeb rau kev ua tiav qhov chaw du thiab lub teeb ci siab.

4. Kev tsim kho thiab kev ua pob zeb

Pob zeb diamond pom hniav, laum khoom, txiav hlau, thiab lwm yam yog dav siv nyob rau hauv kev ua cov ntaub ntawv hauv tsev xws li granite, marble, thiab pob zeb. Piv nrog rau cov cuab yeej ib txwm siv, cov cuab yeej pob zeb diamond yog qhov zoo tshaj plaws hauv kev txiav ceev, kev pab cuam lub neej, thiab kev txiav zoo, thiab tshwj xeeb tshaj yog tsim nyog rau kev ua haujlwm zoo ntawm cov khoom siv hauv tsev thiab cov khoom siv high-density.

5. Lub zog tshiab thiab aerospace

Nrog rau txoj kev loj hlob ntawm lub zog tshiab thev naus laus zis, qhov kev thov rau pob zeb diamond abrasives hauv kev ua cov lithium roj teeb ncej, ceramic diaphragms, hluav taws xob tsheb Cheebtsam, thiab lwm yam yog loj hlob sai. Nyob rau hauv lub tshav pob ntawm aerospace, cov cuab yeej pob zeb diamond yog siv rau precision machining ntawm lub cav kub kawg Cheebtsam, composite structural qhov chaw, thiab lwm yam., uas txhim kho kev ntseeg tau thiab durability ntawm cov khoom.

III. Xaus

Pob zeb diamond abrasives, raws li ib qho tseem ceeb cov khoom siv rau niaj hnub kev lag luam kev lag luam, tau txais los ntawm ntau thiab ntau high-precision machining scenarios vim lawv lub cev zoo heev thiab siv dav. Nyob rau hauv lub neej yav tom ntej, nrog kev nce qib ntawm cov ntaub ntawv tshawb fawb thiab kev tsim technology, pob zeb diamond abrasives yuav txuas ntxiv txhim kho kom zoo dua qub, txawj ntse thiab tus phooj ywg ib puag ncig, pab kev lag luam high-end kev lag luam txav mus rau qib siab dua.