Cov khawv koob ntawm lub ntiaj teb microscopic, coj koj mus rau decipher nano-electroplating

Nyob rau hauv lub era ntawm kev loj hlob sai ntawm science thiab technology,nanotechnology Nws zoo li lub hnub qub ci ntsa iab tshiab, ci ntsa iab hauv ntau thaj chaw thaj tsam. Raws li kev siv tshuab electroplating, nano-electroplating ua ke nrog nanotechnology nrog cov txheej txheem electroplating. Los ntawm kev qhia nanomaterials los yog tswj cov nanostructure ntawm txheej thaum lub sij hawm electroplating txheej txheem, ib txheej nrog zoo heev kev kawm tau txais. Lub hauv paus tseem ceeb yog siv cov khoom tshwj xeeb ntawm nanoparticles, xws li thaj chaw tshwj xeeb ntawm qhov chaw, kev ua haujlwm siab thiab cov khoom siv lub cev thiab tshuaj lom neeg tshwj xeeb, txhawm rau txhim kho kev ua haujlwm ntawm cov txheej txheem electroplating. Thaum lub sij hawm electroplating txheej txheem, nanoparticles yuav dispersed nyob rau hauv cov tshuaj electroplating li additives. Raws li cov txheej txheem electroplating pib, cov nanoparticles yuav muab tso rau ntawm qhov chaw ntawm lub substrate thiab tsim ib txheej txheej nrog lwm cov electroplating ions. Cov txheej no tsis tsuas yog muaj kev tiv thaiv thiab kho kom zoo nkauj ntawm cov tsoos electroplating txheej, tab sis kuj muaj qhov zoo ntawm kev ua tau zoo.

Ⅰ. Lub ntsiab kev ua tau zoo ntawm nano-electroplating txheej

1. Hardness thiab hnav tsis kam

Vim qhov sib ntxiv ntawm nanoparticles, lub hardness ntawm electroplating txheej tau zoo heev. Piv txwv li, tom qab ntxiv nano-pob zeb diamond particles rau cov tsoos nickel-phosphorus electroplating, lub hardness ntawm txheej yuav nce ntau zaus los yog txawm kaum ob zaug. Cov txheej txheem siab tawv no muaj cov ntawv thov dav dav hauv kev ua tshuab, aerospace, tsheb tsim thiab lwm yam. Nws tuaj yeem txo qhov hnav ntawm cov khoom siv kho tshuab thiab txuas ntxiv lub neej kev pabcuam ntawm cov khoom siv, thaum tseem txhim kho qhov raug thiab kev ntseeg siab ntawm cov khoom siv.

2. Corrosion kuj

Kev tiv thaiv corrosion ntawm nano-electroplating txheej kuj tau zoo heev. Nanoparticles tsim ib qho tshwj xeeb microstructure hauv txheej. Cov qauv no tuaj yeem tiv thaiv kev cuam tshuam ntawm corrosive media, yog li txhim kho corrosion kuj ntawm txheej. Piv txwv li, cov txheej txheem tsim los ntawm kev sib xyaw electroplating ntawm nano-ceramic hais thiab hlau ions muaj ob peb zaug lossis txawm kaum ob lub sij hawm siab dua corrosion dua li cov txheej txheem electroplating. Cov txheej no tuaj yeem siv dav hauv marine engineering, cov khoom siv tshuaj lom neeg, cov khoom siv hluav taws xob thiab lwm yam kev lag luam los muab kev tiv thaiv kev tiv thaiv mus ntev rau cov khoom siv.

3. Optical zog

Nano-electroplating txheej kuj muaj qhov tshwj xeeb kho qhov muag. Vim qhov loj me me ntawm cov nanoparticles, thaum lub teeb yog irradiated rau saum npoo ntawm txheej, tshwj xeeb tawg tawg, nqus thiab cuam tshuam phenomena tshwm sim. Piv txwv li, txheej txheej tsim los ntawm kev sib xyaw electroplating ntawm nano-silver hais thiab hlau ions tuaj yeem nthuav tawm cov teebmeem kev kho qhov muag, xws li xim hloov thiab nce gloss. Cov txheej no tuaj yeem siv rau cov khoom siv kho qhov muag, kho kom zoo nkauj thiab lwm qhov chaw, ntxiv qhov pom kev pom zoo rau cov khoom

4. Cov khoom siv hluav taws xob

Cov khoom hluav taws xob ntawm nano-electroplating txheej kuj tau ua kom zoo dua qub. Qee cov nanoparticles muaj qhov tshwj xeeb conductivity lossis semiconductor zog. Thaum lawv tau electroplated nrog hlau ions, lawv tuaj yeem tsim cov txheej txheem nrog cov khoom siv hluav taws xob tshwj xeeb. Piv txwv li, cov txheej txheem tsim los ntawm kev sib xyaw electroplating ntawm nano-carbon raj thiab hlau ions muaj kev ua haujlwm zoo thiab electromagnetic shielding zog. Cov txheej no tuaj yeem siv rau cov khoom siv hluav taws xob, cov khoom siv sib txuas lus thiab lwm yam kev lag luam los txhim kho cov khoom siv hluav taws xob sib raug zoo thiab cov teeb liab kis tau tus mob ntawm cov khoom siv.

Ⅱ. Cov chaw tseem ceeb ntawm nano-electroplating

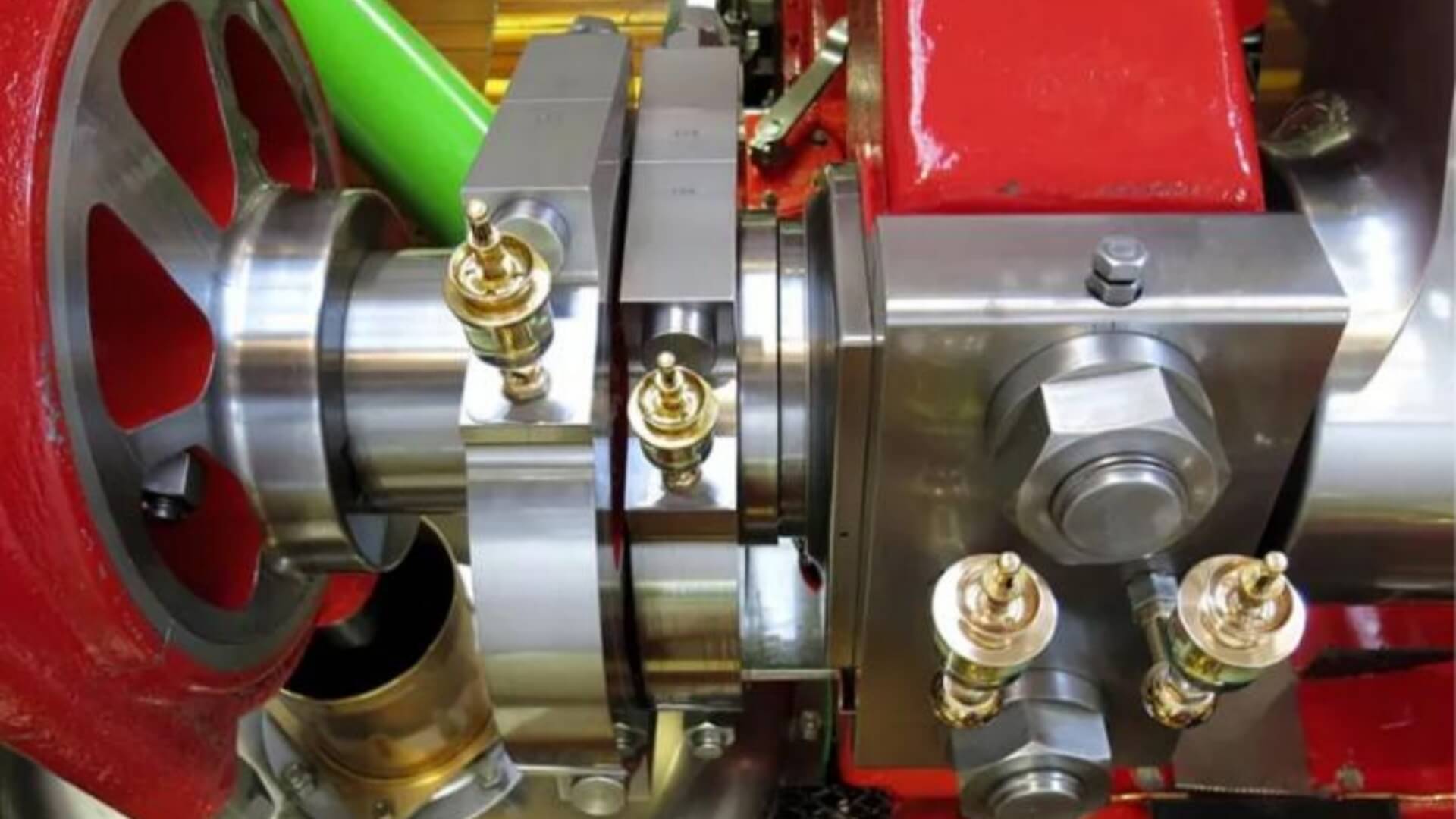

1. Mechanical manufacturing

Vim qhov sib ntxiv ntawm nanoparticles, lub hardness ntawm electroplating txheej tau zoo heev. Piv txwv li, tom qab ntxiv nano-pob zeb diamond particles rau cov tsoos nickel-phosphorus electroplating, lub hardness ntawm txheej yuav nce ntau zaus los yog txawm kaum ob zaug. Cov txheej txheem siab tawv no muaj cov ntawv thov dav dav hauv kev ua tshuab, aerospace, tsheb tsim thiab lwm yam. Nws tuaj yeem txo qhov hnav ntawm cov khoom siv kho tshuab thiab txuas ntxiv lub neej kev pab cuam ntawm cov cuab yeej, thaum tseem txhim kho qhov raug thiab kev ntseeg siab ntawm cov khoom siv.

2. Aerospace

Aerospace teb muaj kev ua tau zoo heev rau cov khoom siv, xav tau lub zog siab, siab hardness, siab hnav tsis kam, siab corrosion kuj thiab lwm yam khoom. Nano-electroplating txheej tuaj yeem ua tau raws li qhov yuav tsum tau ua thiab siv los tsim cov tshuab aerospace, dav hlau txheej txheej, thiab lwm yam. Piv txwv li, coatings tsim los ntawm kev sib xyaw electroplating ntawm nano-ceramic hais thiab hlau ions tuaj yeem txhim kho qhov hnav tsis kam thiab kub tsis kam ntawm lub cav qhov chaw, thaum tseem txo qhov hnyav ntawm qhov chaw thiab txhim kho cov roj efficiency thiab kev ua haujlwm ntawm lub dav hlau.

3. Cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob

Hauv kev lag luam ntawm cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, nano-electroplating txheej tuaj yeem siv los tsim cov khoom siv hluav taws xob zoo thiab cov khoom siv hluav taws xob. Piv txwv li, coatings tsim los ntawm composite electroplating ntawm nano-silver hais thiab hlau ions muaj zoo conductivity thiab antioxidant zog thiab yuav siv tau los tsim high-kev ua tau zoo conductive circuits thiab connectors. Tsis tas li ntawd, nano-electroplating txheej kuj tseem siv tau los tsim cov khoom siv hluav taws xob tiv thaiv hluav taws xob tiv thaiv electromagnetic cuam tshuam thiab txhim kho kev ntseeg tau ntawm cov khoom siv hluav taws xob.

4. Kev lag luam tsheb

Kev lag luam tsheb yog ib qho tseem ceeb ntawm kev siv nano-electroplating. Nano-electroplating txheej tuaj yeem siv los tsim cov tsheb cav, qhov chaw nres tsheb, thiab lwm yam. Piv txwv li, nano-lub cev txheej txheej, txheej txheej tsim los ntawm cov khoom siv electroplating ntawm pob zeb diamond hais thiab hlau ions tuaj yeem txhim kho qhov hnav tsis kam thiab corrosion kuj ntawm lub cav piston rings, yog li txhim kho cov kev pab cuam lub neej thiab kev ua haujlwm ntawm lub cav. Nyob rau tib lub sijhawm, nano-electroplating txheej kuj tuaj yeem siv rau kev kho kom zoo nkauj thiab kev tiv thaiv lub cev ntawm lub tsheb, txhim kho lub glossiness thiab corrosion tsis kam ntawm lub cev thiab txuas ntxiv kev pab cuam lub neej ntawm lub tsheb.