Cov khoom

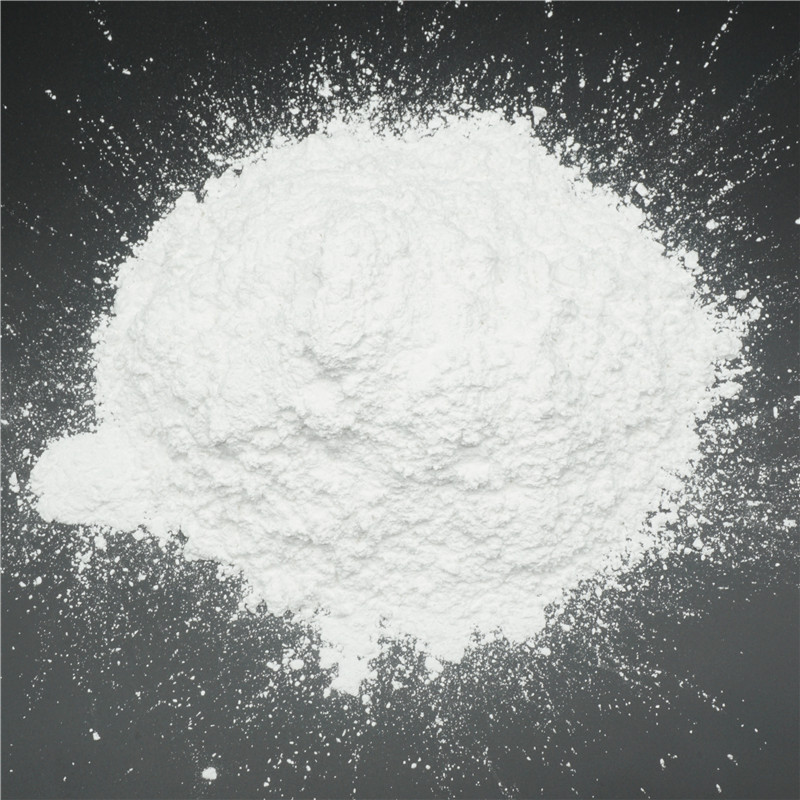

Platelet Calcined Alumina Hmoov

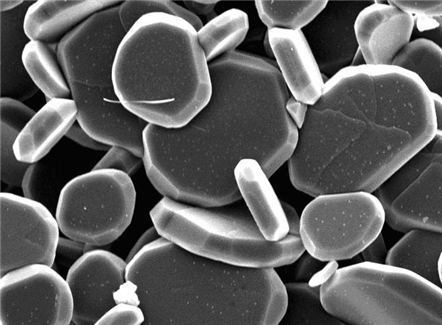

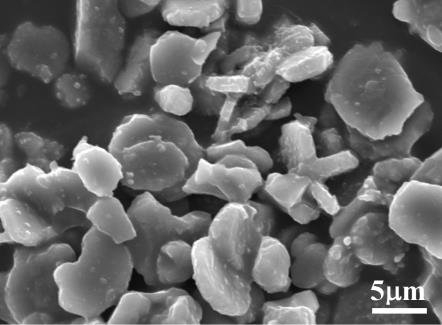

Phaj Calcined Alumina polishing hmoov yog ua los ntawm high-zoo muaj alumina hmoov raws li raw khoom, thiab ua tiav los ntawm ib tug tshwj xeeb ntau lawm txheej txheem. Cov khoom siv lead ua ntawm cov hmoov ua alumina polishing yog hexagonal tiaj tus zoo li cov duab tabular, yog li nws hu ua Platelet Alumina lossis Tabular Alumina.

Platelet Alumina yog cov zoo alumina hom abrasive hmoov, muaj cov phaj zoo li siv lead ua ntawm Al2O3 nrog purity ntau dua 99.0%. Nws muaj cov khoom siv hluav taws xob zoo heev nrog rau kev siv tshuaj lom neeg, thiab tsis corroded los ntawm cov kua qaub lossis alkalines. Raws li qhov loj me me ntawm Platelet Alumina yog nruj tswj hwm, nws tuaj yeem tsim tau zoo heev lapped nto, muab nws superlative zoo li abrasive. Nrog rau ntau yam kev siv, Platelet Alumina yog cov hmoov abrasive uas muaj peev xwm ua tau ntau yam haujlwm.

Tabular alumina hmoov

Tabular alumina hmoov

Standard Specifications rau Particle Loj

| Particle | Particle Distribution (µm) | |||

| Qhov siab tshaj particle | Particle loj | Particle loj | Particle loj | |

| 45 | 82.9 ua | 53.4 ± 3.2 | 34.9 ± 2.3 | 22.8 ± 1.8 |

| 40 | 77.8 ib | 41.8 ± 2.8 | 29.7 ± 2.0 | 19.0 ± 1.0 |

| 35 | 64.0 Nws | 37.6 ± 2.2 | 25.5 ± 1.7 | 16.0 ± 1.0 |

| 30 | 50.8 | 30.2 ± 2.1 | 20.8 ± 1.5 | 14.5 ± 1.1 |

| 25 | 40.3 | 26.3 ± 1.9 | 17.4 ± 1.3 | 10.4 ± 0.8 |

| 20 | 32.0 Nws | 22.5 ± 1.6 | 14.2 ± 1.1 | 9.00 ± 0.80 |

| 15 | 25.4 | 16.0 ± 1.2 | 10.2 ± 0.8 | 6.30 ± 0.50 |

| 12 | 20.2 | 12.8 ± 1.0 | 8.20 ± 0.60 | 4.90 ± 0.40 |

| 9 | < 16.0 | 9.70 ± 0.80 | 6.40 ± 0.50 | 3.60 ± 0.30 |

| 5 | 12.7 Nws | 7.20 ± 0.60 | 4.70 ± 0.40 | 2.80 ± 0.25 |

| 3 | 10.1 | 5.20 ± 0.40 | 3.10 ± 0.30 | 1.80 ± 0.30 |

Tus Qauv Zoo

| Hom khoom | Specific Gravity | ||||

| Al2O3 | SiO 2 | Fe2O 3 | Na2O | ||

| 3-45 µm | 3.90 Nws | ua 99.0 | 0.20 | 0.10 | 1.00 Nws

|

Alumina hmoov zoo

1. Sib piv nrog lwm cov hmoov tabular, tabular alumina hmoov muaj cov khoom ua ke zoo heev. Xws li cov ntsiab lus siab melting, muaj zog hardness, siab mechanical zog, zoo hnav tsis kam, tshuaj tsis haum, oxidation kuj thiab kub tsis kam thiab lwm yam.

2. Cov ntawv tiaj tus ua kom muaj kev sib txhuam loj dua, txhim kho kev sib tsoo ceev thiab kev ua haujlwm zoo, qhov no tuaj yeem txo cov tshuab sib tsoo, kev ua haujlwm thiab sijhawm sib tsoo.

3. Cov ntawv tiaj tus ua rau cov khoom sib tsoo tsis yooj yim rau khawb, tus nqi ntawm cov khoom tsim nyog tuaj yeem nce 10%-15%. Piv txwv li, tus nqi tsim nyog semiconductor silicon wafer tuaj yeem ncav cuag 96% lossis ntau dua.

4. Muaj qhov cuam tshuam ob npaug ntawm nano thiab micro hmoov, qhov kev ua haujlwm saum npoo yog nruab nrab, tsis tsuas yog tuaj yeem ua ke nrog lwm pab pawg ua haujlwm, tab sis kuj tsis yooj yim rau agglomerate thiab pab txhawb kom muaj txiaj ntsig zoo.

5. Nws muaj adhesion zoo, tiv thaiv kev tiv thaiv tseem ceeb thiab muaj peev xwm los cuam tshuam lub teeb.

6. Tabular alumina hmoov yog yuav luag pob tshab, tsis muaj xim, thiab muaj ib tug tiaj tus thiab du nto. Cov crystallized zoo yog cov hexagons tsis tu ncua.

7. Tabular alumina hmoov yuav ua tau zoo heev polishing hmoov.

1. Electronics kev lag luam: sib tsoo thiab polishing ntawm semiconductor monocrystalline silicon wafers, quartz quartz muaju, compound semiconductors (crystalline gallium, phosphating nano).

2. Kev lag luam iav: sib tsoo thiab ua cov khoom siv lead ua, quartz iav, kinescope iav plhaub npo, iav kho qhov muag, kua siv lead ua kua (LCD) iav substrate, thiab quartz siv lead ua.

3. Kev lag luam txheej: txheej txheej tshwj xeeb thiab muab tso rau hauv cov tshuaj plasma.

4. Hlau thiab ceramic ua kev lag luam: precision ceramic cov ntaub ntawv, sintered ceramic raw khoom, qib high-temperature coatings, thiab lwm yam.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.