Cov khoom

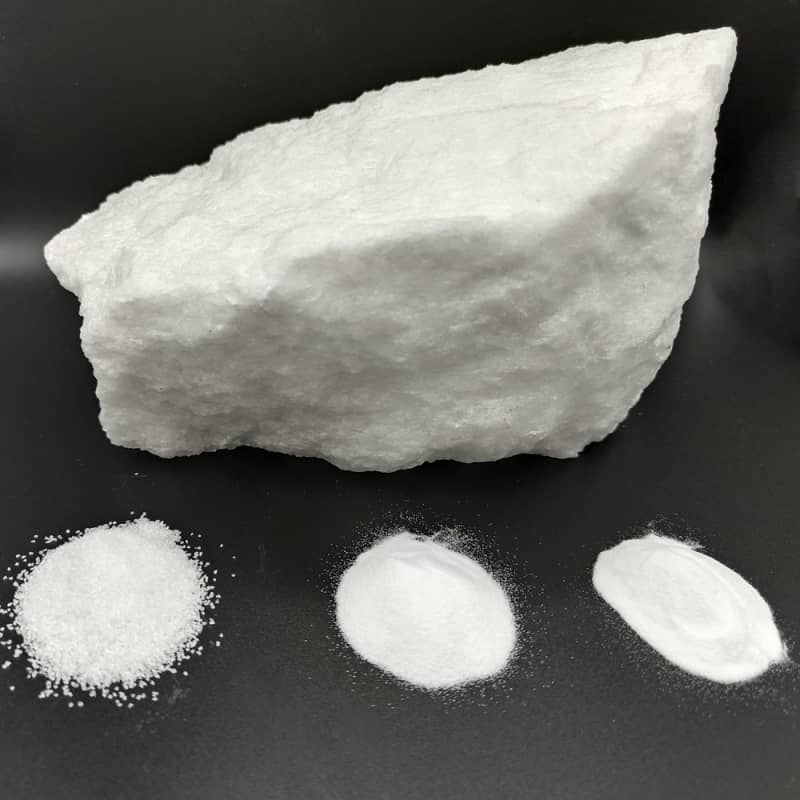

Abrasive Khoom Dawb Fused Alumina Grits

Dawb fused alumina yog alumina hmoov li raw khoom, tsis tu ncua sib cais rau cov khoom siv hluav taws xob arc yog siab tshaj xim av fused alumina yog me ntsis, me ntsis qis toughness, muaj zog txiav quab yuam thiab tshuaj stability yog zoo, muaj cov rwb thaiv tsev zoo heev.

Dawb fused alumina yog ua los ntawm high-purity low-sodium alumina hmoov los ntawm melting ntawm kub, txias crystallization, thiab ces crushing.Cov dawb fused alumina grit yog nyob rau hauv kev tswj nruj kom cov nplej loj faib thiab zoo ib yam.

Feem ntau siv nyob rau hauv ladle castables, hlau khiav cov ntaub ntawv, refractory gunning mix ntaub ntawv thiab lwm yam monolithic refractory khoom;

Rau cov ntaub ntawv zoo li tus refractory, nws yog tsuas yog siv nyob rau hauv high-zoo raw khoom ntawm corundum cib, corundum mullite, refining steel ntxeem tau plug cib, ib tug tseem ceeb tshuaj tsuag phom, steelmaking thiab nruam casting kev lag luam.

Nws kuj tuaj yeem siv los ua cov ntaub ntawv polishing, precision casting, txau thiab txheej, tshwj xeeb ceramics

Dawb, α siv lead ua ntau dua 99%, siab purity, siab hardness, thiab siab toughness, muaj zog txiav quab yuam, muaj zog tshuaj stability, thiab muaj zog rwb thaiv tsev.

| Mohs hardness | 9 |

| Qhov ntom ntom | 1.75-1.95g / cm3 |

| Tshwj xeeb lub ntiajteb txawj nqus | 3.95g / cm3 |

| Volume ceev | 3.6 |

| Melting degree | 2250 ℃ |

| Refractory degree | 2000 ℃ |

Siv rau refractory, castable

| Cov khoom | 0-1 1-3 3-5m / m | F100 F200 F325 | |||

| Guarantee Tus nqi | Tus nqi | Guarantee Tus nqi | Tus nqi | ||

| Tshuaj muaj pes tsawg leeg | Al2O3 | ≥99.1 | 99.5 ua | ≥98.5 | 99 |

| SiO 2 | ≤0.4 | 0.06 ib | ≤ 0.30 | 0.08 ib | |

| Fe2O 3 | ≤0.2 | 0.04 ib | ≤ 0.20 | 0.1 | |

| Na2O | ≤0.4 | 0.3 | ≤ 0.40 | 0.35 Nws | |

Siv rau abrasives, blasting, sib tsoo

| Yam khoom | Cov nplej | ||

| 8 # 10 # 12 # 14 # 16 # 20 # 22 # 24 # 30 # 36 # 40 # 46 # 54 # 60 # 70 # 80 # 90 # 100 # 120 # 150 # 180 # 220 # | |||

| Guarantee Tus nqi | Tus nqi | ||

| Tshuaj muaj pes tsawg leeg | Al2O3 | ≥99.1 | 99.5 ua |

| SiO 2 | ≤0.2 | 0.04 ib | |

| Fe2O 3 | ≤0.2 | 0.03 ib | |

| Na2O | ≤ 0.30 | 0.2 | |

Siv rau abrasives, lapping, Polishing

| Yam khoom | Micropowder | |||

| “W” | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W 0.5 | |||

| “FEPA” | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | |||

| “JIS” | 240 # 280 # 320 # 360 # 400 # 500 # 600 # 700 # 800 # 1000 # 1200 # 1500 # 2000 # 2500 # 3000 # 4000 # 6000 # 1800 # | |||

| Guarantee Tus nqi | Tus nqi | |||

| Tshuaj muaj pes tsawg leeg | Al2O3 | ≥99.1 | 99.3 ua | |

| SiO 2 | ≤0.4 | 0.08 ib | ||

| Fe2O 3 | ≤0.2 | 0.03 ib | ||

| Na2O | ≤0.4 | 0.25 | ||

1.Tsis muaj kev cuam tshuam txog cov xim ntawm cov khoom ua tiav.

2.Nws tuaj yeem siv rau hauv cov txheej txheem uas cov hlau hmoov seem raug txwv nruj heev.

3.Shaping nplej yog heev haum rau ntub sandblasting thiab polishing hauj lwm.

1.Sandblasting, polishing thiab sib tsoo ntawm cov hlau thiab iav.

2.Filling ntawm cov xim, hnav-resistant txheej, ceramic, thiab glaze.

3.Kev sib tsoo log, ntawv xuab zeb thiab emery ntaub.

4.Production ntawm ceramic lim membranes, ceramic raj, ceramic daim hlau.

5.Rau kev siv hauv pem teb hnav-resistant.

6.Sandblasting ntawm Circuit Court boards.

7.Sandblasting ntawm ships, aircraft cav, tsheb ciav hlau lem thiab txheej lub cev.

8.Various dawb fused aluminium oxide nplej tuaj yeem ua raws li cov neeg siv khoom sib txawv.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.