Cov khoom

B80 Zirconia ZrO2 Ceramic Blasting Media

Ceramic Beads Blasting Media

Zirconium Oxide Sand, tseem hu ua ceramic xuab zeb, yog tsim los ntawm zirconium dioxide, silicon dioxide thiab txhuas trioxide nyob rau hauv ib tug tshwj xeeb formulation thiab raug rho tawm haujlwm nyob rau hauv ntau tshaj 2250 degrees, tshwj xeeb tshaj yog haum rau kev kho deg ua hauj lwm ntawm complex workpieces ntawm hlau thiab yas qauv, txhim kho lub neej qaug zog ntawm workpiece nto thiab tshem tawm burrs thiab ya.

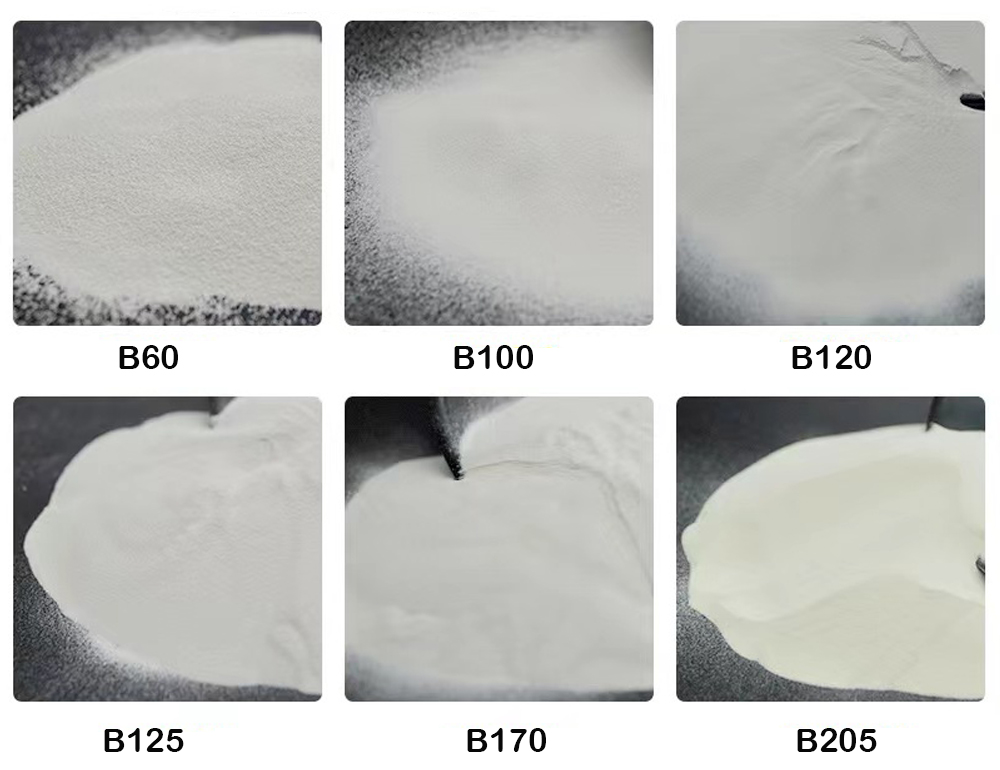

Ceramic Sand Specifications

| Specification | Grain loj (mm los yog um) |

| B20 | 0.600-0.850 hli |

| B30 | 0.425-0.600 hli |

| B40 | 0.250-0.425 hli |

| B60 | 0.125-0.250 hli |

| B80 | 0.100-0.200 hli |

| B120 | 0.063-0.125 hli |

| B170 | 0.040-0.110 hli |

| B205 | 0.000-0.063 hli |

| B400 | 0.000-0.030 hli |

| B505 | 0.000-0.020 hli |

| B600 | 25 ± 3.0 hli |

| B700 Nws | 20 ± 2.5 hli |

| B800 Nws | 14.5 ± 2.5 hli |

| B1000 | 11.5 ± 2.0 hli |

| ZrO2 | SiO 2 | Al2O3 | Qhov ntom | Stacking ceev | Hardness siv qhov tseem ceeb | |

| 60-70% | 28-33% | <10% | 3.5 | 2.3 | 700 (HV) | 60 HRC (HR) |

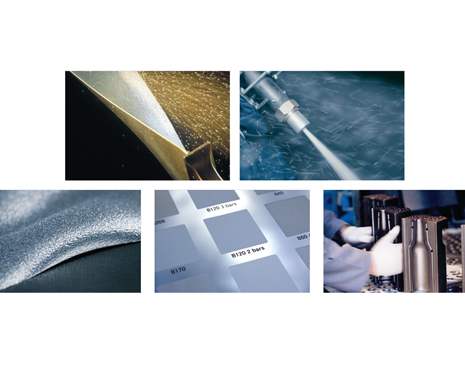

Engineered mus rau qhov zoo tshaj plaws tus qauv

Txhawm rau xa cov qauv zoo tshaj plaws thiab zoo ib yam, cov hlaws zoo nkauj zoo nkauj tau dhau los ua cov txheej txheem tswj xyuas tag nrho nrog rau kev tshuaj xyuas cov khoom zoo los ntawm cov thev naus laus zis xws li particle loj laser diffraction thiab morphological duab. Qhov no ua rau cov neeg siv khoom kom ua tiav cov khoom tawg nrog cov khoom zoo meej thiab ruaj khov.

Blast-cleaning:

- Ntxuav cov hlau nplaum nrog tshem tawm cov khoom (cov nyhuv abrasive)

- Tshem tawm xeb thiab nplai los ntawm cov hlau nplaum

- Tshem tawm cov xim tempering

Nto finishing:

- Tsim kom muaj matt tiav ntawm qhov chaw

- Ua kom pom cov teebmeem tshwj xeeb

Lwm yam:

- Roughening metallic nto

- Tsim kom muaj matt tiav ntawm iav

- Deburring

- Ua cov khoom nyuaj heev

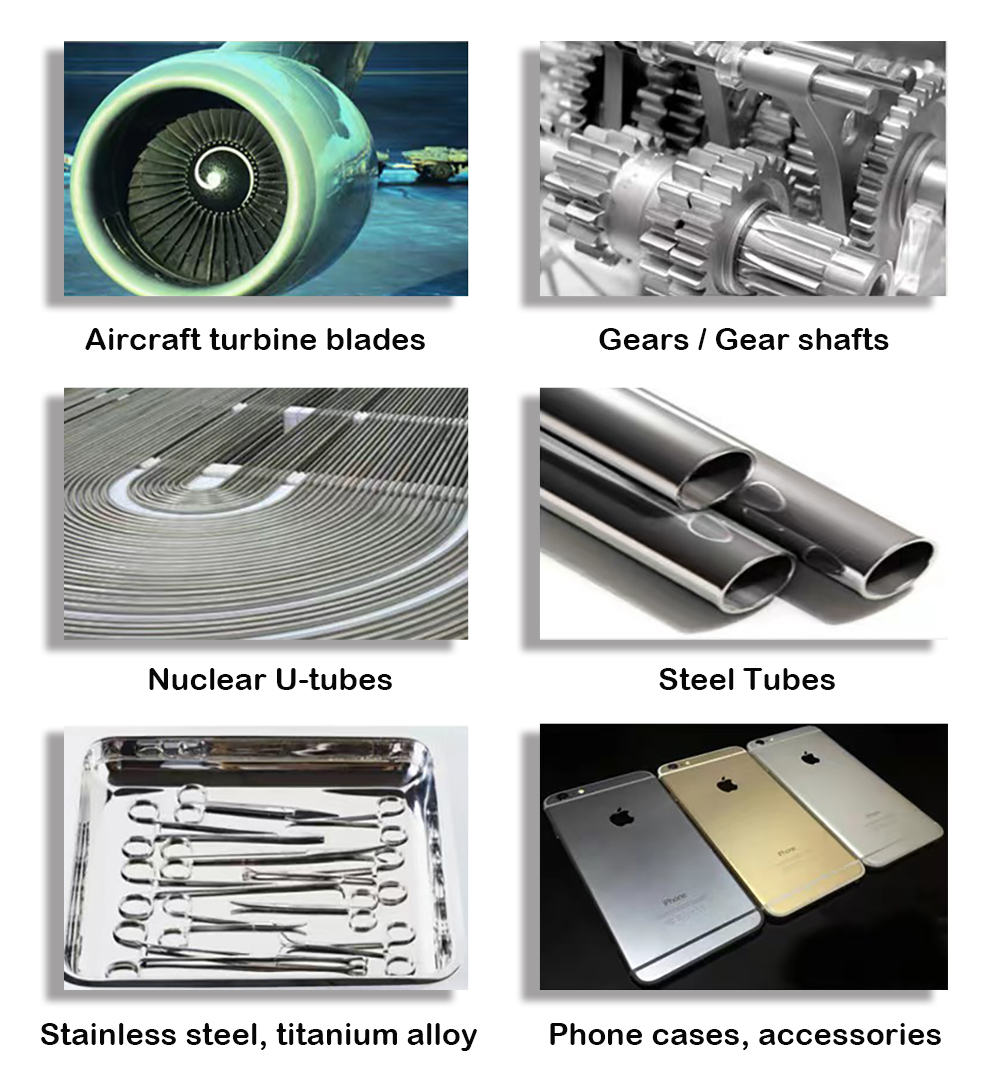

- Aerospace khoom siv:tsim thiab kho cov ntaub ntawv titanium alloy.

- Kev lag luam pwm thiab tuag:tu thiab tu

- Hlau ua haujlwm:kev txhawb zog, kev ua kom zoo nkauj

- Plastics, electronics kev lag luam:deburring ntawm Circuit Court boards, aesthetic teebmeem

- Automotive kev lag luam:tiv thaiv qaug zog thiab ntxiv dag zog rau kev kho mob ntawm lub caij nplooj ntoos hlav poob siab

- Kev lag luam turbine:deg qaug zog kho thiab ntxiv dag zog ntawm turbine hniav

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.