Cov khoom

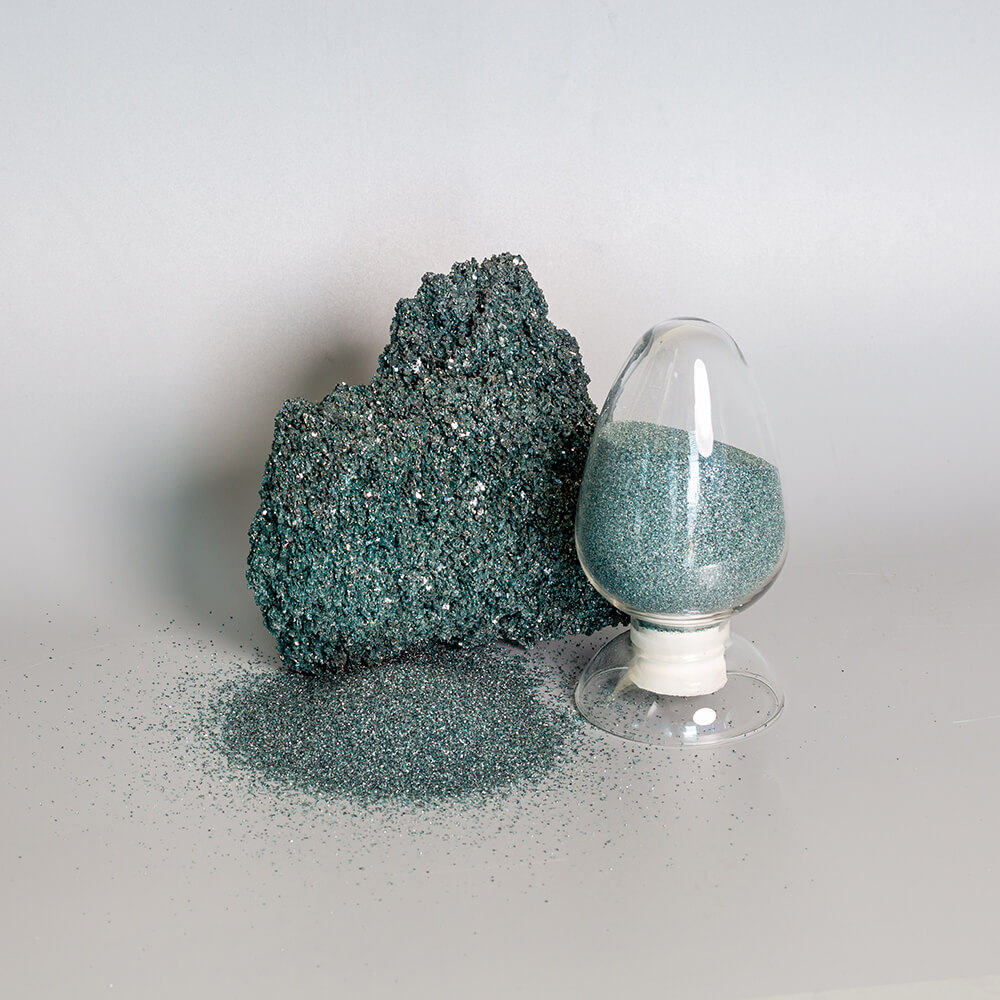

Green Silicon Carbide Hmoov rau Bonded Silicon Carbide Sib Tsoo Log

Ntsuab silicon carbide Description

Ntsuab silicon carbide yog ua los ntawm quartz xuab zeb thiab roj av coke los ntawm high-temperature melting. Txoj kev tsim khoom yog qhov tseem ceeb tib yam li cov xim dub silicon carbide, tab sis cov kev cai rau cov khoom siv raw yog txawv. Cov smelted crystals muaj siab purity, siab hardness thiab muaj zog txiav quab yuam, thiab yog haum rau kev ua cov ntaub ntawv nyuaj thiab nkig. Ntsuab silicon carbide yog tsim rau kev sib tsoo nyuaj alloys, nyuaj thiab nkig hlau thiab cov khoom tsis yog xim hlau, xws li cov hlau tsis muaj hlau xws li tooj liab, tooj dag, txhuas thiab magnesium, thiab cov khoom tsis yog xim hlau xws li pob zeb zoo nkauj, iav kho qhov muag thiab ceramics.

| Physic Properties | |

| Xim | Ntsuab |

| Crystal daim ntawv | Polygon |

| Mohs hardness | 9.2-9.6 |

| Micro hardness | 2840 ~ 3320kg / hli |

| Melting point | 1723 |

| Ua haujlwm kub siab tshaj plaws | 1600 |

| Qhov ntom ntom | 3.21g / cm³ |

| Qhov ntom ntom | 2.30g / cm3 |

| Tshuaj muaj pes tsawg leeg | |||

| Cov nplej | Tshuaj muaj pes tsawg leeg (%) | ||

| Sic | FC | Fe2O 3 | |

| 16#--220# | ≥99.0 | ≤ 0.30 | ≤ 0.20 |

| 240 # - 2000 # | ≥98.5 | ≤0.50 | ≤ 0.30 |

| 2500 #-4000 # | ≥98.5 | ≤ 0.80 | ≤0.50 |

| 6000 # - 12500 # | ≥98.1 | ≤ 0.60 | ≤ 0.60 |

1.Abrasive: automotive, aerospace, metalworking, thiab hniav nyiaj hniav kub. Nws yog siv rau kev sib tsoo, txiav, thiab polishing ntawm cov hlau tawv thiab ceramics.

2.Refractory: furnaces thiab kilns vim nws cov thermal conductivity thiab tsawg thermal expansion.

3.Electronics: LEDs, cov khoom siv fais fab, thiab cov khoom siv microwave vim nws cov hluav taws xob zoo heev thiab thermal stability.

4.Solar zog: hnub ci vaj huam sib luag

5. Metallurgy

6.Ceramics: txiav cov cuab yeej, hnav-tiv taus qhov chaw, thiab cov khoom kub-kub

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.