Cov khoom

Siab Ntshiab 95% Zro2 2mm Yttrium / yttria Stabilized Zirconia hlaws / pob

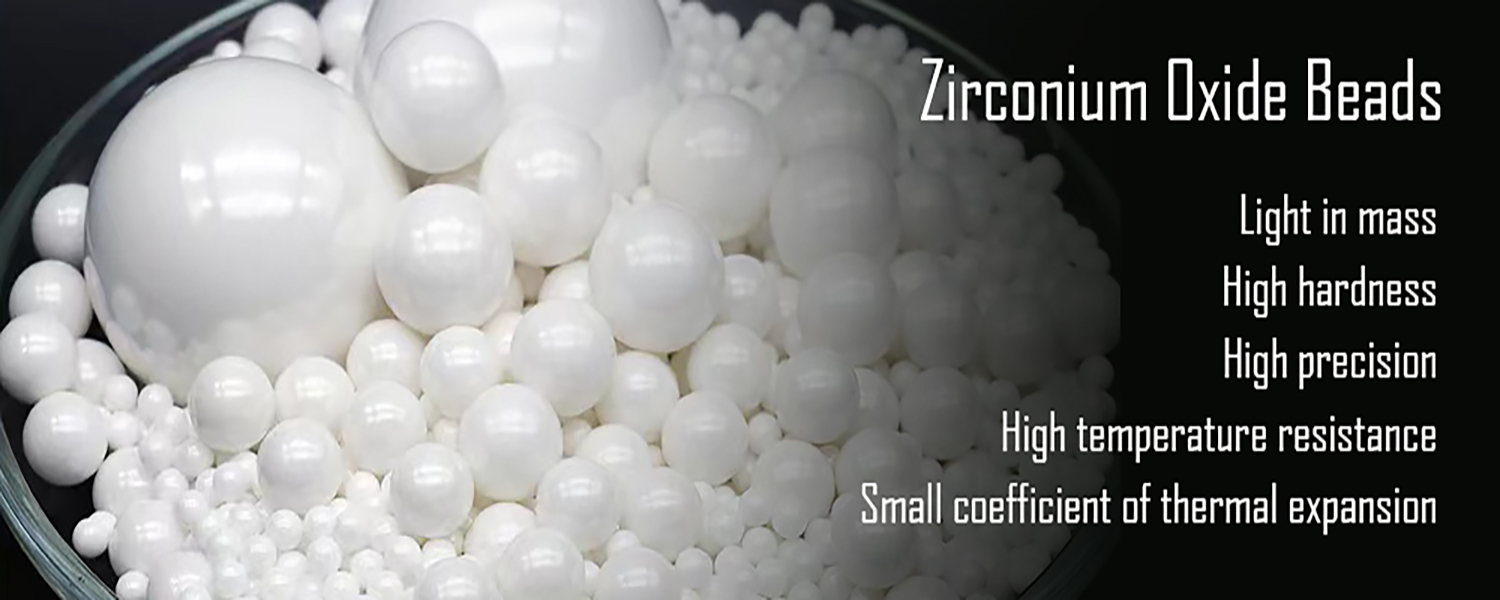

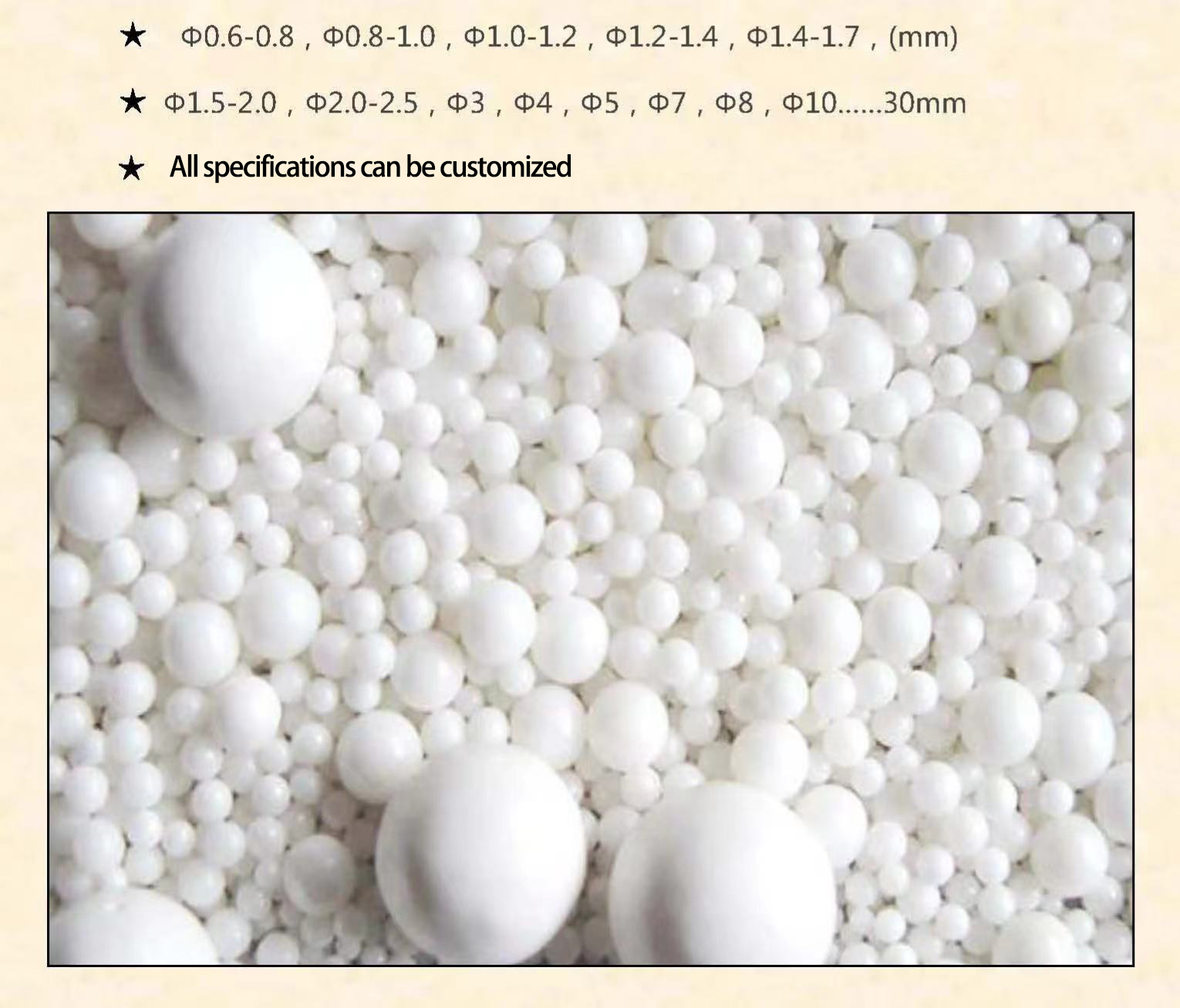

Zirconium Oxide hlaws

| Khoom Parameters | ||

| Pawg | Chav ntsuas ntsuas | Tus nqi |

| Kev sib xyaw | wt% | 94.6% ZrO2,5.4Y2O3 |

| Tshwj xeeb ceev | g/cm3 | ≥5.95 |

| Hardness (HV) | HRA | > 10 |

| Thermal expansion | X 10-6 / K | 11 |

| Coefficient (20400) | ||

| Elastic modulis | GPa | 205 |

| Fracture toughness | Mpa·m 1/2 | 7-10 |

| Khoov zog | MPa | 1150 |

| Cov qoob loo loj | Um | <0.5 |

| Thermal conductivity | w/(m·k) | 3 |

Qhov zoo

Daim ntawv thov zirconia hlaws

1.Bio-tech (DNA, RNA & protein extraction thiab cais tawm)

2.Chemicals xws li Agrochemicals xws li fungicides, insecticides thiab herbicides

3.Coating, xim, luam ntawv thiab inkjet inks

4. Tshuaj pleev ib ce (Lipsticks, daim tawv nqaij & hnub tiv thaiv cream)

5. Cov khoom siv hluav taws xob thiab cov khoom siv xws li CMP slurry, ceramic capacitors, lithium hlau phosphate roj teeb

6.Minerals xws li TiO2, Calcium Carbonate thiab Zircon

7. Pharmaceuticals

8.Pigments thiab dyes

9.Flow tis nyob rau hauv cov txheej txheem technology

10.Vibro-sib tsoo thiab polishing ntawm cov hniav nyiaj hniav kub, gemstones & aluminium log

11.Sintering txaj nrog zoo thermal conductivity, tuaj yeem tswj tau qhov kub thiab txias

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.