Cov khoom

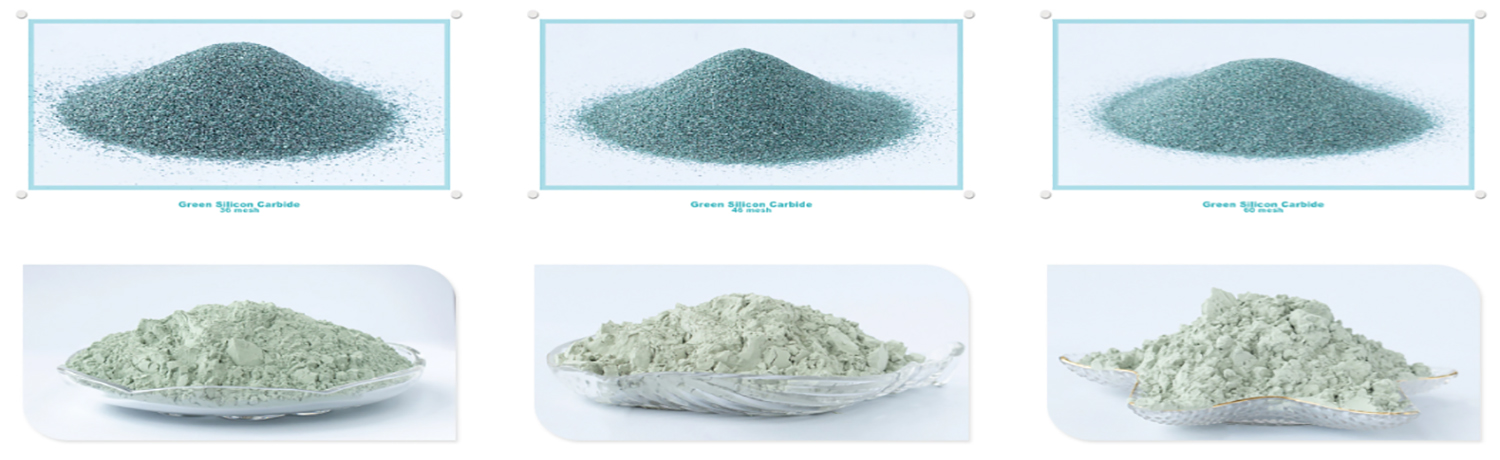

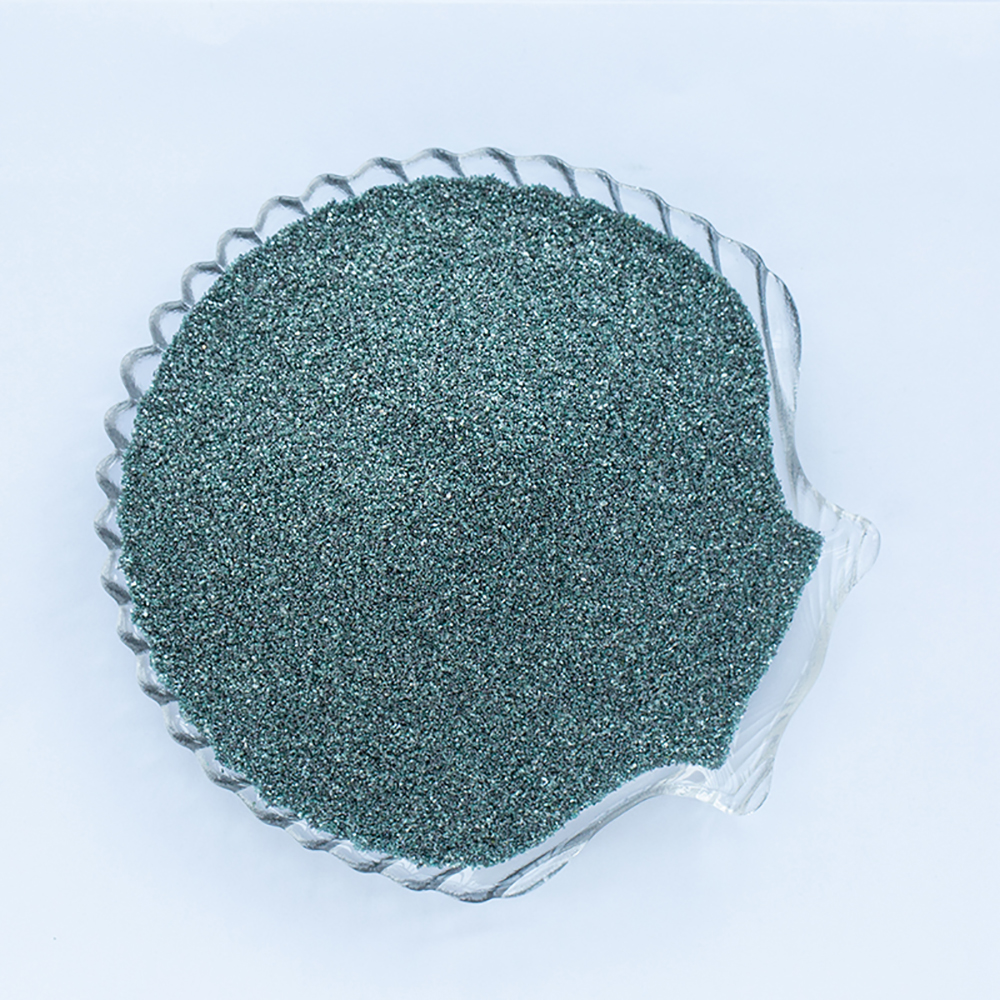

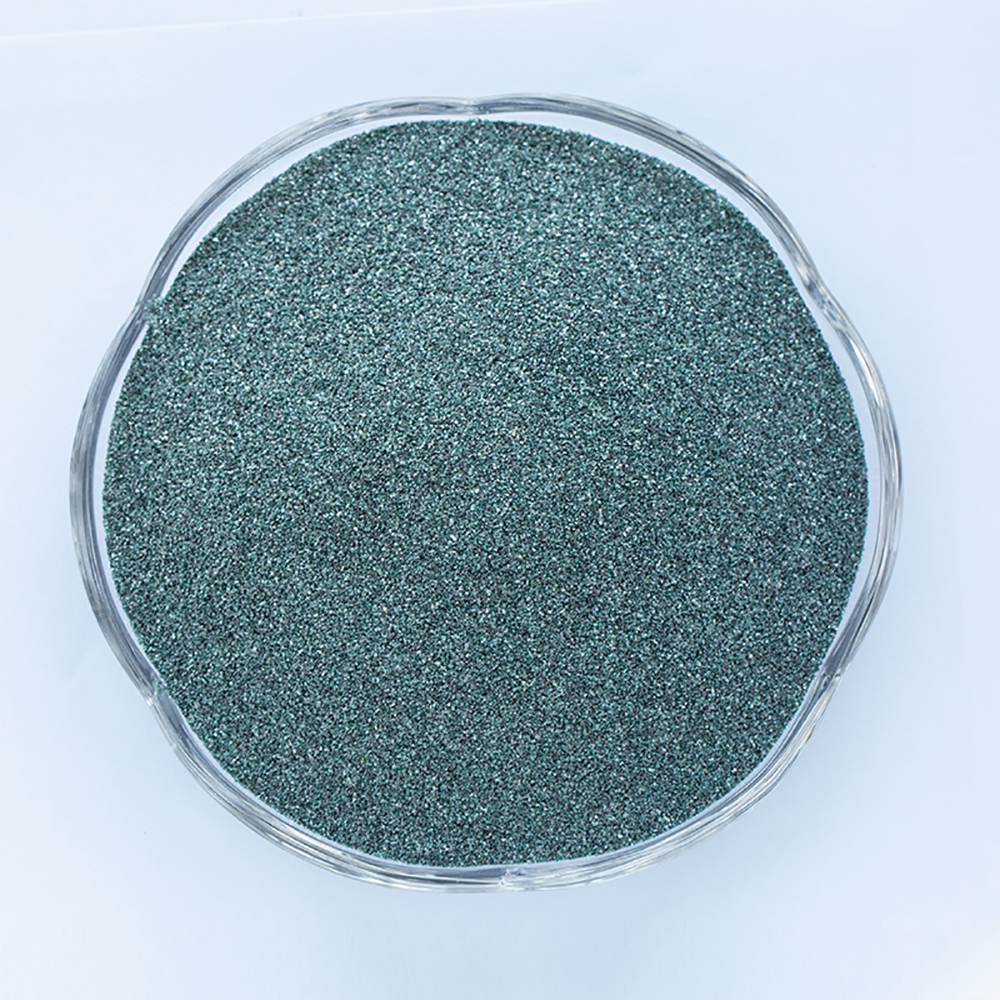

High-Quality Crushed Green Silicon Carbide rau Polishing thiab sib tsoo

Green Silicon Carbide Description

Ntsuab silicon carbide yog cov khoom siv zoo abrasive ua los ntawm silicon carbide nplej thiab roj av coke nyob rau hauv lub qhov cub hluav taws xob ntawm qhov kub thiab txias.

Green Silicon Carbide Grit Loj

| Sandblasting qib | 8 # 10 # 12 # 14 # 16 # 20 # 22 # 24 # 30 # 36 # 40 # 46 # 54 # 60 # 70 # 80 # 90 # 100 # 120 # 150 # 180 # 220 # |

| Polishing qib | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 |

| 240 # 280 # 320 # 360 # 400 # 500 # 600 # 700 # 800 # 1000 # 1200 # 1500 # 2000 # 2500 # 3000 # 4000 # 6000 # 1800 | |

| Nco tseg: peb kuj tuaj yeem kho raws li cov neeg siv khoom xav tau. | |

Green Silicon Carbide Chemistry thiab Bulk Density

| Tshuaj ntsuam xyuas | Bulk Density: LPD = Loose Pack Density | ||||||

| Grit No. | Min.% SiC | Max.% C | Max.%SiO2 | Max.% Si | Max.% MI | Min. | Max. |

| 8# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.35 Nws | 1.43 ib |

| 10# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.35 Nws | 1.44 ib |

| 12# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.41 ib | 1.49 ib |

| 14# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.42 ib | 1.50 ib |

| 16# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.43 ib | 1.51 ib |

| 20# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.44 ib | 1.52 ib |

| 22# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.44 ib | 1.52 ib |

| 24 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.45 Nws | 1.53 ib |

| 30# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.45 Nws | 1.53 ib |

| 36# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.46 ib | 1.54 ib |

| 40# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.47 ib | 1.55 ib |

| 46# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.47 ib | 1.55 ib |

| 54 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.46 ib | 1.54 ib |

| 60 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.46 ib | 1.54 ib |

| 70 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.45 Nws | 1.53 ib |

| 80 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.44 ib | 1.52 ib |

| 90 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.44 ib | 1.51 ib |

| 100# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.42 ib | 1.50 ib |

| 120# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.40 Nws | 1.48 ib |

| 150 # | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.38 ib | 1.46 ib |

| 180# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.38 ib | 1.46 ib |

| 220# | 99.00 Nws | 0.40 Nws | 0.40 Nws | 0.50 ib | 0.0200 Nws | 1.36 ib | 1.44 ib |

1.Abrasive: Ntsuab silicon carbide yog dav siv los ua cov khoom abrasive nyob rau hauv ntau yam lag luam, xws li tsheb, aerospace, metalworking, thiab hniav nyiaj hniav kub.

2.Refractory: furnaces thiab kilns vim nws cov thermal conductivity thiab tsawg thermal expansion.

3.Electronics: LEDs, cov khoom siv fais fab, thiab cov khoom siv microwave

4.Solar zog: hnub ci vaj huam sib luag.

5. Metallurgy

6.Ceramics: txiav cov cuab yeej, hnav-tiv taus qhov chaw, thiab cov khoom kub-kub

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.

daim ntawv nug

Sau koj cov lus ntawm no thiab xa tuaj rau peb