Cov khoom

Polishing thiab Sib Tsoo Micropowder Aluminium Oxide Hmoov rau Sintering Corundum thiab Ceramics

Aluminium Oxide Hmoov Description

Alumina hmoovyog high-purity, nplua-grained khoom ua los ntawmAluminium oxide (Al2O3)uas yog dav siv nyob rau hauv ib tug ntau yam ntawm industrial daim ntaub ntawv.Nws yog cov hmoov dawb crystalline uas feem ntau ua los ntawm kev ua kom zoo ntawm bauxite ore.

Aluminium Oxide Hmoov Specification

| Lub cev muaj zog: | |

| Xim | Dawb |

| Qhov tshwm sim | Hmoov |

| Mohs hardness | 9.0-9.5 Nws |

| Melting point (ºC) | 2050 |

| Kub taw tes (ºC) | 2977 ib |

| Qhov ceev ceev | 3.97 g / cm3 |

| Specification | Al2O3 | Na2O | D50 (hli) | Tus thawj crystal particles | Kev ceev ceev |

| 0.7 ua | ≥99.6 | ≤ 0.02 | 0.7-1.0 Nws | 0.3 | 2-6 |

| 1.5 ua | ≥99.6 | ≤ 0.02 | 1.0-1.8 Nws | 0.3 | 4-7 |

| 2.0 ua | ≥99.6 | ≤ 0.02 | 2.0-3.0 Nws | 0.5 | <20 |

Aluminium oxide hmoov (Al2O3) yog cov khoom siv ntau yam uas pom tau ntau daim ntawv thov thoob plaws ntau yam kev lag luam.

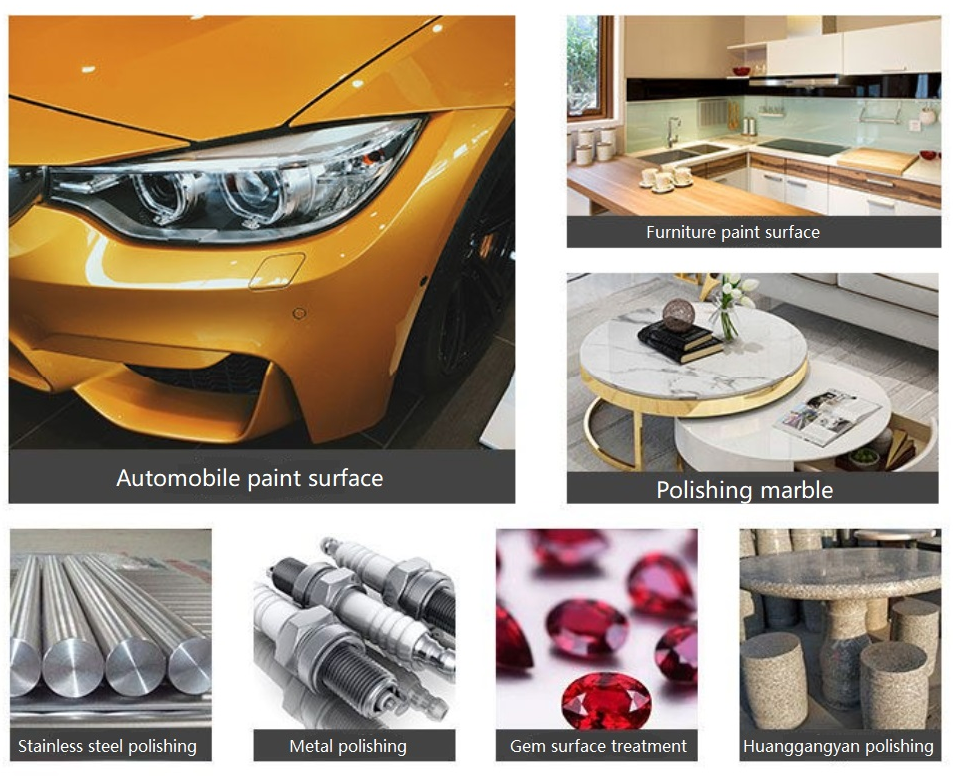

- Abrasives: sib tsoo log, ntawv xuab zeb, polishing compounds, thiab abrasive blasting media

- Refractories: hauv ob sab phlu, kilns, thiab lwm yam khoom siv kub kub

- Coatings: thermal spraying lossis tshuaj vapor deposition los tsim cov txheej txheem tiv thaiv

- Catalysts: petrochemical, tshuaj, thiab tshuaj industries

- Hluav taws xob rwb thaiv tsev: Circuit Court boards, insulators, thiab high-voltage insulating cov ntaub ntawv

- Ceramics: ceramic substrates, cov khoom siv hluav taws xob, cov cuab yeej txiav, thiab qhov hnav-tiv taus.

- Additive Manufacturing: xaiv laser sintering (SLS) los yog binder jetting

- Fillers thiab Pigments

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.

daim ntawv nug

Sau koj cov lus ntawm no thiab xa tuaj rau peb