Cov khoom

Synthetic Pob Zeb Diamond Polishing Micro Powder

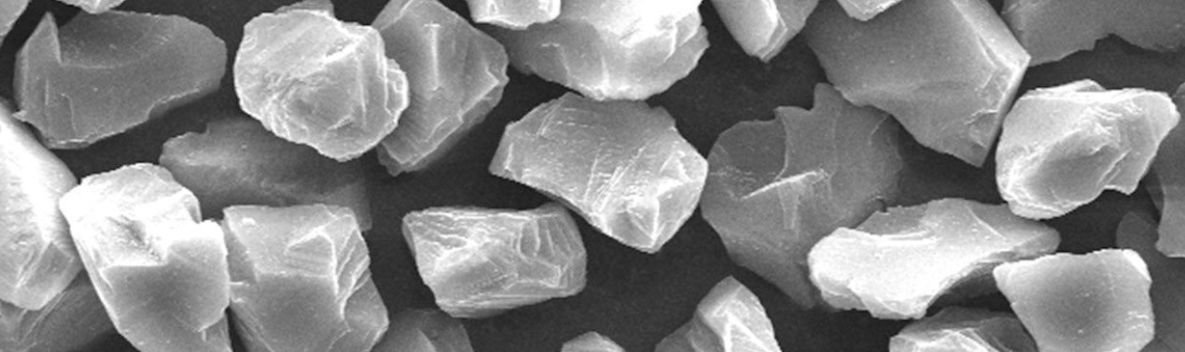

Monocrystalline Pob Zeb Diamond Hmoov

Monocrystalline Pob Zeb Diamond Powder yog tsim los ntawm cov khoom siv pob zeb diamond ib leeg siv lead ua abrasive nplej los ntawm txoj kev siab zoo li qub, uas yog crushed thiab zoo li siv cov txheej txheem tshwj xeeb rau cov ntaub ntawv nyuaj. Nws cov khoom khaws cov khoom siv lead ua ib leeg ntawm ib lub pob zeb diamond.

| Specification | D50 (μm) | Specification | D50 (μm) |

| 0-0.05 Nws | 0.05 Nws | 5-10 | 6.5 |

| 0-0.08 Nws | 0.08 ib | 6-12 | 8.5 |

| 0-0.1 hli | 0.1 | 8–12 | 10 |

| 0-0.25 Nws | 0.2 | 8–16 | 12 |

| 0-0.5 hli | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 hli | 0.8 ua | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

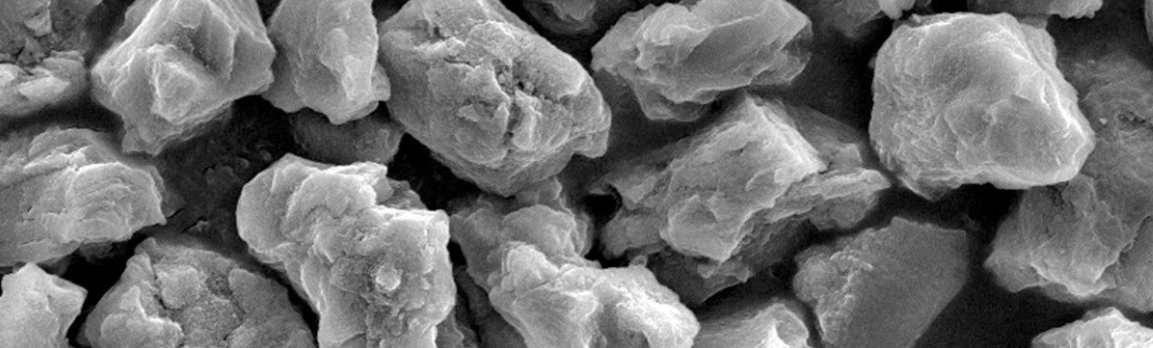

Polycrystalline Pob Zeb Diamond Powder

Polycrystalline pob zeb diamond hmoov yog micron thiab sub-micron polycrystalline particles muaj li ntawm pob zeb diamond nplej nrog ib txoj kab uas hla ntawm 5 ~ 10nm sib raug zoo los ntawm unsaturated bonds. Sab hauv yog isotropic thiab tsis muaj cleavage dav hlau. Nws muaj siab toughness. Vim nws cov yam ntxwv tshwj xeeb, nws feem ntau siv rau kev sib tsoo thiab polishing cov ntaub ntawv semiconductor, precision ceramics, thiab lwm yam.

Muaj qhov ntau thiab tsawg ntawm pob zeb diamond micro hmoov yog raws li hauv qab no:

Cov yam ntxwv ntawm cov khoom

-Oversize kiag li tshem tawm

-Nroj PSD

-Nto purity tuaj yeem ncav cuag qib ppm

- Zoo dispersibility

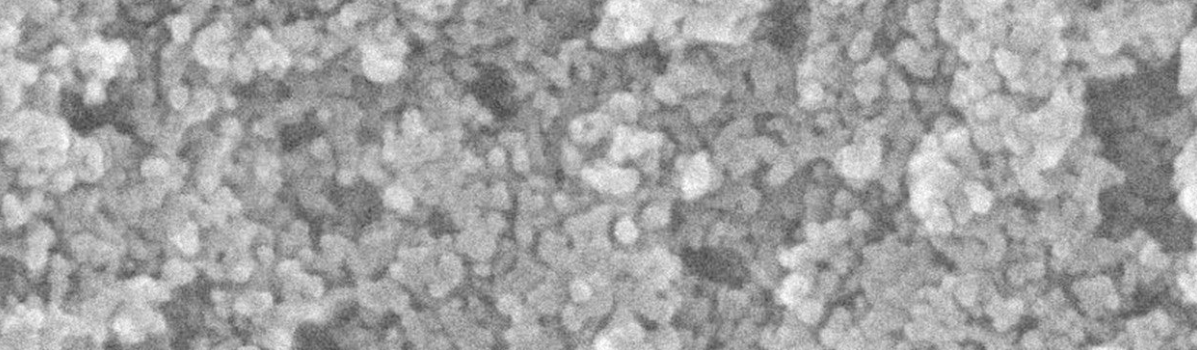

Nano Pob Zeb Diamond Powder

Nano pob zeb diamond hmoov yog tsim nrog cov pob zeb me me hauv qab 20 nanometer, qhov tshwj xeeb detonative mob ua rau lub ntsej muag zoo li pob zeb diamond nrog cov pab pawg neeg nplua nuj nyob rau saum npoo, nws thaj chaw tshwj xeeb yog nce los ntawm ib qho kev txiav txim ntawm qhov sib txawv nrog cov pob zeb diamond monocrystalline. Cov khoom no tsis tsuas yog muaj qhov zoo heev hardness thiab sib tsoo cov yam ntxwv ntawm pob zeb diamond, tab sis kuj muaj cov yam ntxwv tshiab ntawm nanofunctional cov ntaub ntawv.

| Qhov ntau thiab tsawg | NPE 50 | NPE 80 | NPE 100 | NPE 120 | NPE 150 | NPE 200 | NPE 300 | NPE 500 | NPE 800 |

| D50 (nm) | 45-55 : kuv | 75-85 : kuv | 90-110 : kuv | 110-130 : kuv | 140-160 : kuv | 180-220 : kuv | 280-320 : kuv | 450-550 | 750-850 : kuv |

Yam ntxwv

Monocrystalline Pob Zeb Diamond Hmoov Daim Ntawv Thov

1. Haum rau ntau yam high-precision electroplated pob zeb diamond xov hlau, electroplated pob zeb diamond sib tsoo log, SiC siv lead ua txiav, riam, ultra-thin saw hniav, thiab lwm yam.

2. Haum rau pob zeb diamond composite sheets, pob zeb diamond polycrystalline thiab hlau daim ntawv cog lus khoom, ceramic bond khoom, electroplated pob zeb diamond khoom, thiab lwm yam.

3. Haum rau cov cuab yeej electroplated pob zeb diamond, sib tsoo lub log, thiab lwm yam tshwj xeeb yog siv rau kev ua cov ntaub ntawv nyuaj thiab nkig.

4. Haum rau precision sib tsoo thiab polishing ntawm high-end precision gems, lo ntsiab muag, metallographic consumables, LCD panels, LCD iav, sapphire, quartz nplooj, LED sapphire substrates, LCD iav, ceramic cov ntaub ntawv, thiab lwm yam.

Polycrystalline Pob Zeb Diamond Daim Ntawv Thov

1. Nyias thiab polishing ntawm semiconductor wafers, xws li SiC wafer thiab sapphire

2.Nto polishing ntawm ntau yam khoom siv ceramic

3.Nto polishing ntawm cov ntaub ntawv hlau, xws li stainless hlau, aluminium alloy thiab lwm yam

Nano Pob Zeb Diamond Daim Ntawv Thov

1. Super zoo polishing. Lub nto roughness ntawm polished workpieces tuaj yeem ncav cuag angstrom-theem yam tsis muaj khawb, uas tuaj yeem ua tau raws li cov ntawv thov polishing nruj tshaj plaws.

2. Nano pob zeb diamond tuaj yeem siv los ua lubricating roj additives. Kev sib txhuam zawv zawg yuav raug hloov mus rau hauv kev sib txhuam dov, uas tuaj yeem txo qhov kev sib txhuam coefficient thiab txhim kho kev sib txhuam kev ua tau zoo thiab tseem ua rau lub neej ua haujlwm ntev.

3. Composite plating thiab txau rau ntawm qhov chaw ntawm ntau yam workpieces, txhim khu kev hnav tsis kam, corrosion kuj, cuam tshuam toughness thiab hardness ntawm workpieces 's nto.

4. Raws li cov roj hmab thiab cov khoom siv ntxiv, nano pob zeb diamond tuaj yeem txhim kho nws cov hnav tsis kam, puncture tsis kam, tensile khoom thiab tseem ua rau cov txheej txheem kev laus qeeb.

5. High purity nano pob zeb diamond yuav tsis ua rau lom rejection, lub caij no nws yuav tau lug siv nyob rau hauv kev kho mob, lom thiab tshuaj pleev ib ce teb vim hais tias ntawm nws loj tshwj xeeb deg cheeb tsam, muaj zog adsorption muaj peev xwm.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.