Cov khoom

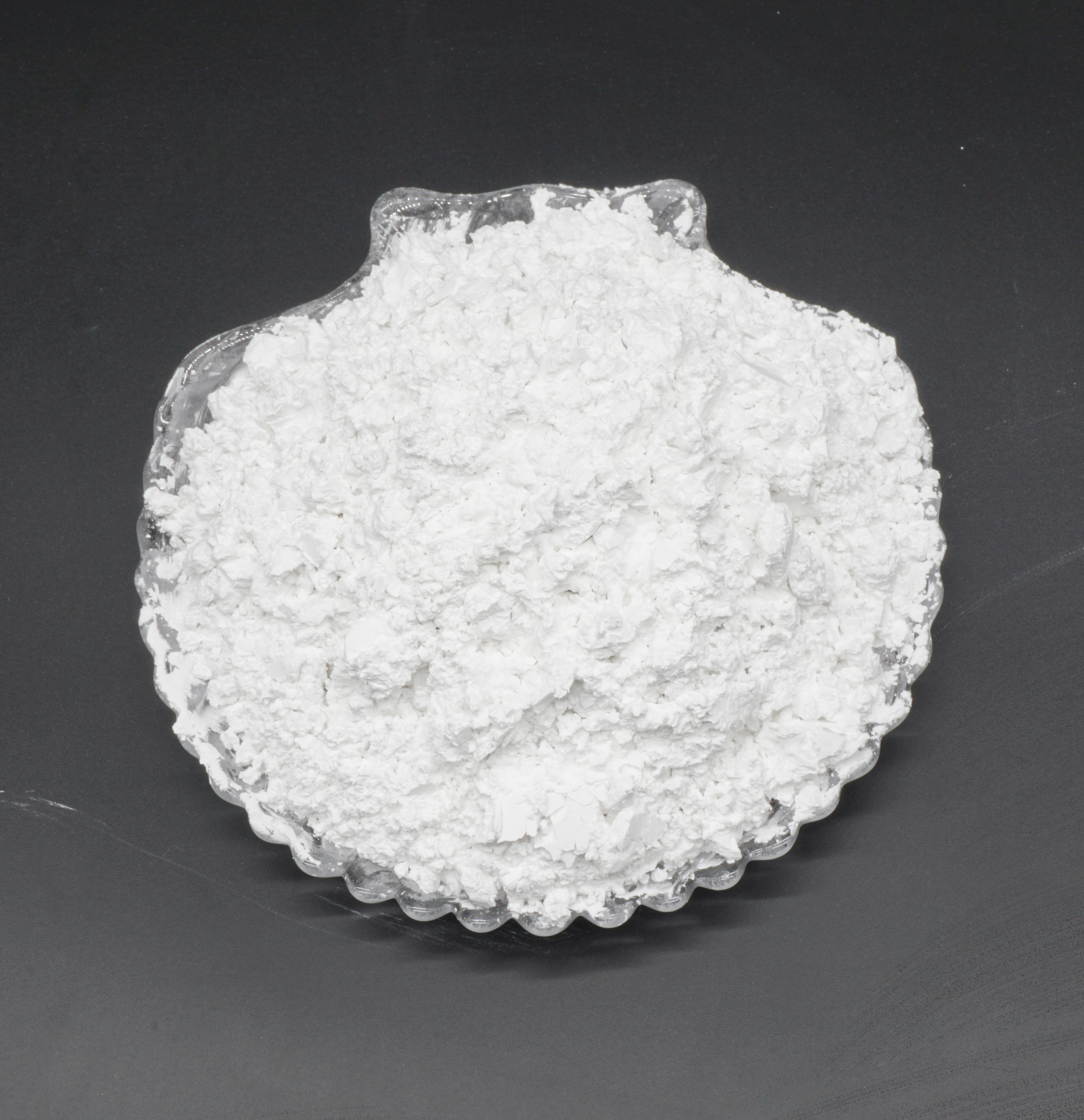

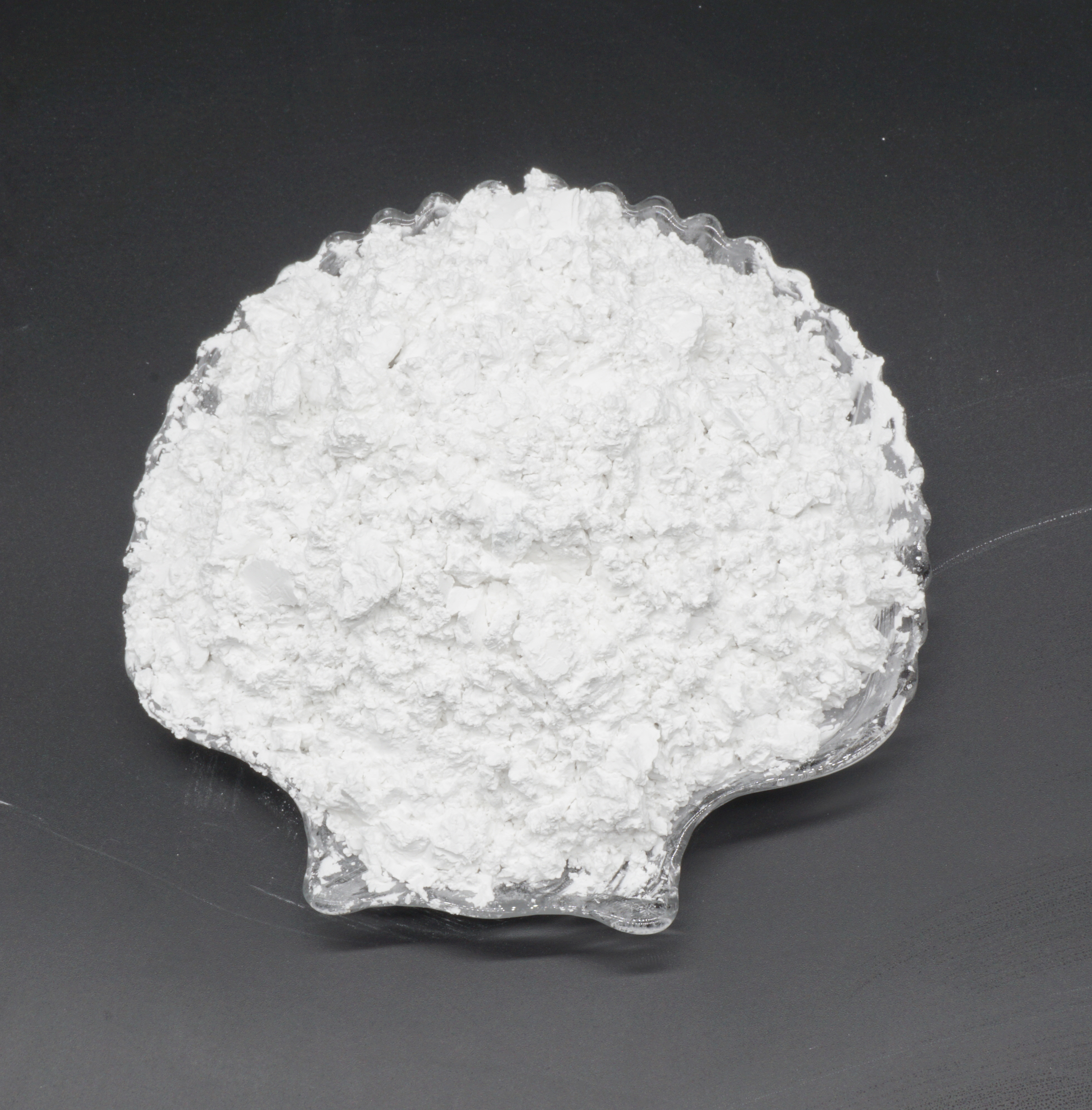

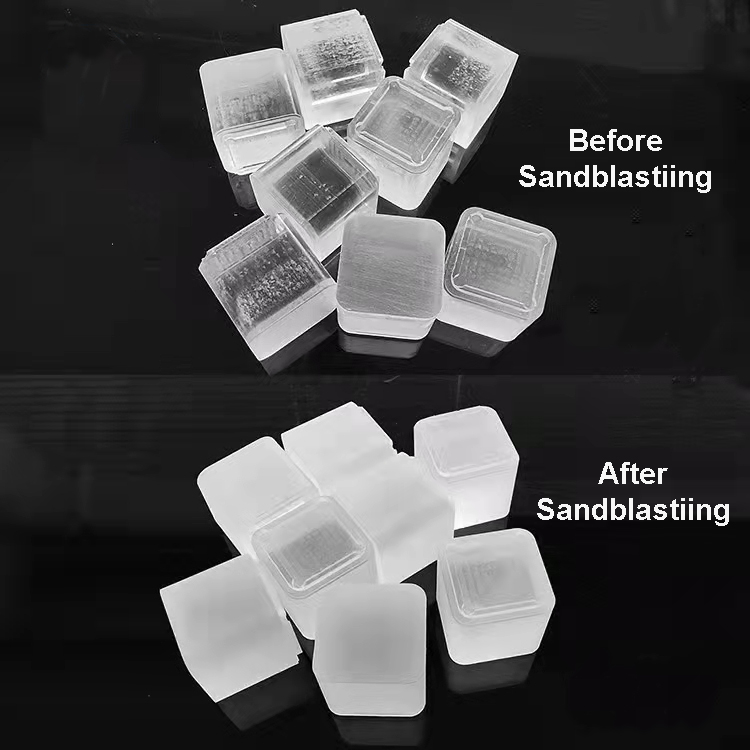

Sib tsoo Blasting Polishing Media 240 #-12500 # Dawb Fused Alumina Hmoov

WFA Description

Dawb corundum nrog muaj alumina hmoov raws li raw khoom, nyob rau hauv lub arc tom qab 2000 degrees kub melting tom qab txias, sib tsoo thiab shaping, sib nqus sib cais kom tshem tawm hlau, tshuaj ntsuam mus rau hauv ib tug ntau yam ntawm granularity, nws ntom ntom ntom, siab hardness, particles tsim ib Lub kaum ntse ntse, haum rau kev tsim cov ceramics, resin consolidation abrasive cov cuab yeej thiab sib tsoo, polishing, sandblasting, precision casting (kev nqis peev casting tshwj xeeb corundum), thiab lwm yam. Nws tuaj yeem siv los tsim cov khoom siv qib siab refractory.

Chemical thiab Physical Composition

| Qauv: 240 #,280 #,320#,360 #,400 #,500 #,600 #,700 #,800 #,1000#,1200 #,1500 #,2000#,2500 #,3000 #,4000 #,6 000 #,8 000 #,1 0 0 0 0 #,12500 # | |||

| chamical kev ntsuam xyuas (%) | lub cev muaj zog | ||

| Al2O3 | ≥99.2 | xim | dawb |

| SiO 2 | ≤ 0.04 | siv lead ua | a-Al2O3 |

| NaO 2 | ≤ 0.22 | qhov ntom ntom | 1.75-1.95g / cm3 |

| Fe2O 3 | ≤ 0.04 | ceev ceev | 3.95-3.97g / cm3 |

| K2O | ≤ 0.01 | mosh hardness | 9,0 nqi |

| kev siv | polishing, blasting, txheej, sib tsoo, thiab lwm yam. | ||

Kev siv WFA

1. Ua pob tshab ceramics: high-pressure sodium teeb, EP-ROM qhov rais.

Αlpha-Al2O3 tuaj yeem sintered rau hauv pob tshab ceramic siv los ua cov khoom siv hluav taws xob siab sodium teeb;raws li tau zoo raws li yuav siv tau raws li ib tug compact fluorescent teeb nyob rau hauv lub tiv thaiv txheej ntawm phosphor txheej los txhim kho teeb lub neej.

2. Raws li qib siab polishing cov ntaub ntawv rau: iav, hlau, semiconductor cov ntaub ntawv, yas, daim kab xev, sib tsoo siv, thiab lwm yam.

3. Raws li additive: txhawb cov xim, roj hmab, yas hnav-resistant.

Raws li cov khoom sib xyaw tshiab, Al2o3 hmoov tuaj yeem siv los ua kom muaj zog ntxiv thiab ntxiv, xws li ntxiv alumina nanoparticles rau hauv roj hmab, hnav tsis kam tuaj yeem txhim kho ntau zaus.

4. Siv raws li catalyst, catalyst cab kuj, analytical reagent.

Los ntawm kev tsim txiaj ntawm nws cov khoom tshwj xeeb, Al2o3 hmoov yog dav siv los ua catalyst thiab nws cov cab kuj, hauv ceramics thiab lwm yam.

5. Siv rau txheej

Alumina nanoparticles ua cov khoom siv kho qhov muag thiab cov txheej txheem tiv thaiv saum npoo ntawm cov khoom tuaj yeem nqus tau ultraviolet lub teeb, thiab nyob rau hauv qee qhov wavelengths ntawm lub teeb excitation tuaj yeem tsim nrog cov particle loj ntawm lub wavelength ntawm lub teeb.

6.Siv rau siab zog ceramic

Hauv cov ntawv thov ceramic, precision ceramics ua los ntawm nano alumina hmoov muaj cov hlau zoo sib xws thiab tawv, lub teeb yuag, tshwj xeeb, txhim khu lub zog zoo.

Los ntawm kev ntxiv me me ntawm nano-alumina nyob rau hauv cov pa ceramic matrix tuaj yeem ua rau cov khoom siv hluav taws xob ntawm cov khoom siv ob npaug los txhim kho cov tawv nqaij ntawm cov ceramics kom txo tau nws qhov kub thiab txias.

- Siv rau kev sib tsoo dawb, xws li iav kev lag luam.

2. Siv rau cov khoom sib txhuam thiab hnav-resistant pem teb.

3. Haum rau resin los yog ceramic bond abrasive, xws li sib tsoo log, txiav tawm sib tsoo log, thiab lwm yam.

4. Haum rau refractory, hnav-tiv taus thiab refractory khoom.

5. Siv rau polishing, xws li grindstone, sib tsoo thaiv, phaj tig, thiab lwm yam.

6. Siv rau txheej abrasive cov cuab yeej, xws li ntawv xuab zeb, emery daim ntaub, xuab zeb siv, thiab lwm yam.

7. Siv rau precision casting, sib tsoo, sib tsoo, polishing pwm ntau lawm.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.