Cov khoom

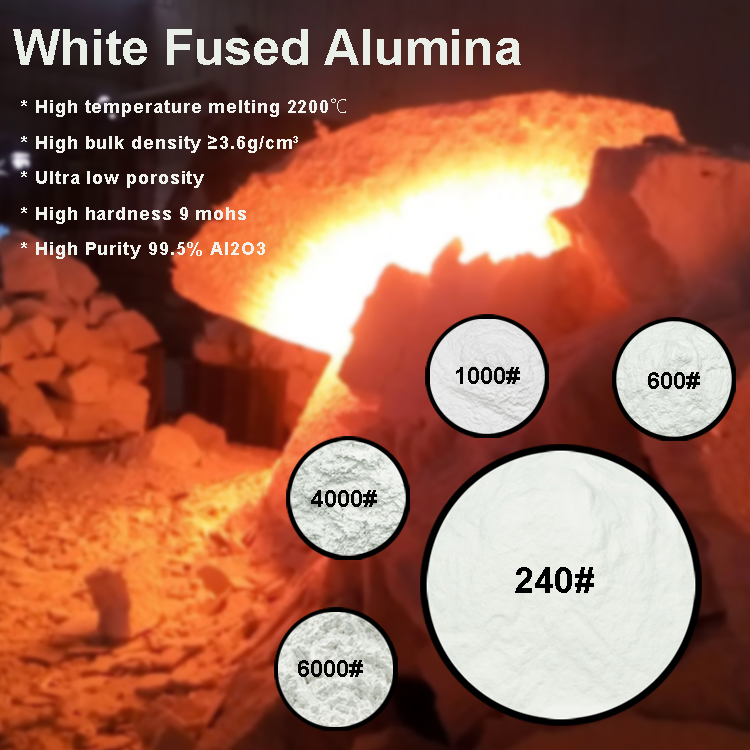

WA Dawb Fused Alumina Dawb Corundum Hmoov Sib Tsoo Blasting Polishing Abrasive Khoom

Dawb fused alumina abrasive

Dawb corundum yog ib tug dawb abrasive ua los ntawm industrial alumina hmoov (Al2O3) nrog rau cov ntsiab lus ntawm ntau tshaj 98% thiab ib tug me me ntawm hlau oxide thiab silicon oxide.Nws yog ib qho dawb abrasive uas yog melted ntawm qhov kub thiab txias.Nws hardness yog me ntsis siab dua li cov xim av corundum thiab nws toughness yog me ntsis qis.Nws yog tsim los ntawm smelting thiab txias tshaj 2000 degrees nyob rau hauv arc, sib tsoo thiab shaping, tshem tawm hlau los ntawm sib nqus sib cais, thiab sieving rau ntau yam granularity.Nws yog compact nyob rau hauv kev ntxhib los mos, siab hardness thiab ntse nyob rau hauv cov duab.

Tshuaj muaj pes tsawg leeg

| Siv rau abrasive, blasting, sib tsoo,polishing, txheej | |||

| Yam khoom | 240 #,280 #,320#,360 #,400 #,500 #,600 #,700 #,800 #,1000#,1200 #,1500 #,2000#,2500 #,3000 #,4000 #,6 000 #,8 000 #,1 0 0 0 0 #,12500 # | ||

| Guarantee Tus nqi | Tus nqi | ||

| Tshuaj muaj pes tsawg leeg | AI2O 3 | 99,0 nqi | 99.5 ua |

| SiO 2 | 0.2 max | 0.06 ib | |

| Fe2O 3 | 0.2 max | 0.04 ib | |

| Na2O | 0.3 max | 0.30 Nws | |

| Cov khoom kuaj | ntsuas |

| Mohs hardness | 9.0 ib |

| Qhov ntom ntom | 1.75-1.95g / cm3 |

| Qhov ceev tiag tiag | 3.95g / cm3 |

| Melting point | 22 500 C |

| Qhov siab tshaj plaws ua haujlwm kub | 19 000 C |

Qhov zoo ntawm Dawb fused alumina:

1, High hardness thiab ntom particles.Ib qho particle roundness yog qhov zoo.

2, Cov xim yog dawb huv, tsis muaj impurities, los xyuas kom meej lub hnav-resistant txheej los yog hnav-resistant ntawv xim thiab pob tshab.

3, Uniform faib ntawm particle loj, ib qho particle zoo ib yam, nrog ib tug me me ntawm hnav - resistant nyhuv.

4, tshuaj stability thiab acid, alkali tsis ua, kub stability yog zoo heev.

Daim ntawv thov Scenario

1.Siv rau kev sib tsoo dawb, xws li iav kev lag luam.

2. Siv rau cov khoom sib txhuam thiab hnav-resistant pem teb.

3. Haum rau resin los yog ceramic bond abrasive, xws li sib tsoo log, txiav tawm sib tsoo log, thiab lwm yam.

4. Haum rau refractory, hnav-tiv taus thiab refractory khoom.

5. Siv rau polishing, xws li grindstone, sib tsoo thaiv, phaj tig, thiab lwm yam.

6. Siv rau txheej abrasive cov cuab yeej, xws li ntawv xuab zeb, emery daim ntaub, xuab zeb siv, thiab lwm yam.

7. Siv rau precision casting, sib tsoo, sib tsoo, polishing pwm ntau lawm.

- Siv rau kev sib tsoo dawb, xws li iav kev lag luam.

2. Siv rau cov khoom sib txhuam thiab hnav-resistant pem teb.

3. Haum rau resin los yog ceramic bond abrasive, xws li sib tsoo log, txiav tawm sib tsoo log, thiab lwm yam.

4. Haum rau refractory, hnav-tiv taus thiab refractory khoom.

5. Siv rau polishing, xws li grindstone, sib tsoo thaiv, phaj tig, thiab lwm yam.

6. Siv rau txheej abrasive cov cuab yeej, xws li ntawv xuab zeb, emery daim ntaub, xuab zeb siv, thiab lwm yam.

7. Siv rau precision casting, sib tsoo, sib tsoo, polishing pwm ntau lawm.

Koj nug

Yog tias koj muaj lus nug. Thov koj xav tiv tauj peb.